Flow meter

推荐资讯

免费咨询热线

+086-0517-86998608Flow meter

一、气体涡轮流量计概述1、 Overview of gas turbine flowmeter气体涡轮流量计采用先进的微处理技术,具有功能强,运算精度高、性能可靠等优点,主要技术指标达到国外同类产品的先进水平。是石油、化工、电力、冶金、工业与民用锅炉等燃气计量和城市天燃气、燃气调压站计量及燃气贸易计量的理想仪表。其工作原理是:当气体进入流量计时,先经过特殊的整流器加速,在流体的作用下,涡轮克服阻力力矩和磨擦力矩开始转动,当力矩达到平衡时,转速稳定,涡轮的转速与气体流量成正比,并经过旋转的发讯盘上···

全国服务热线:+086-0517-86998608

在线咨询-

产品详情

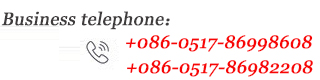

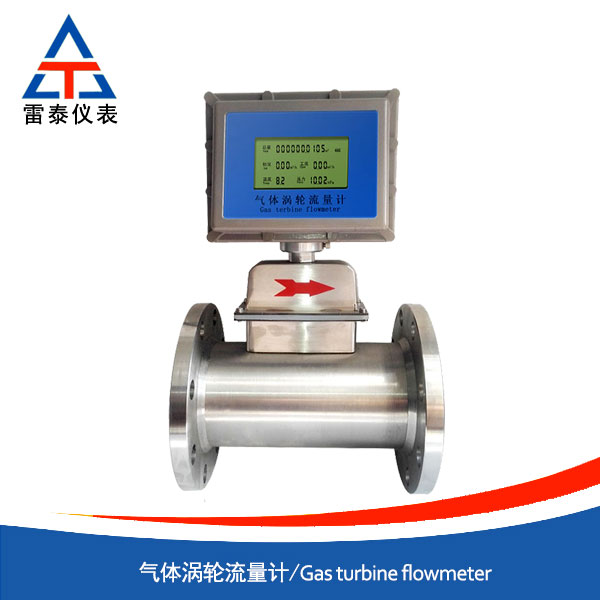

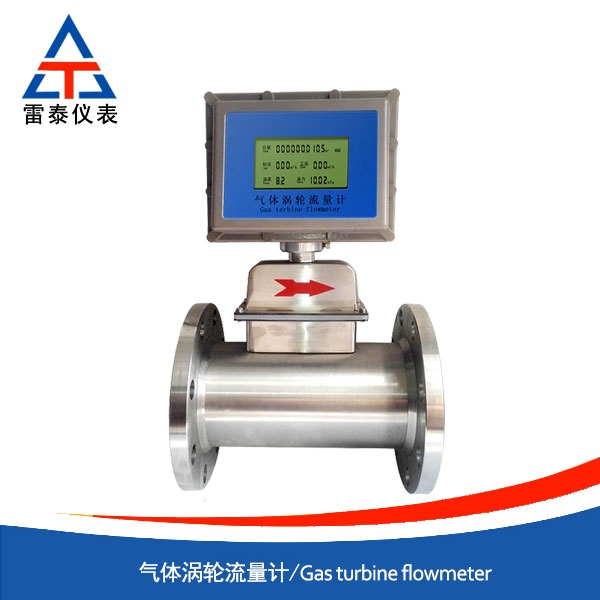

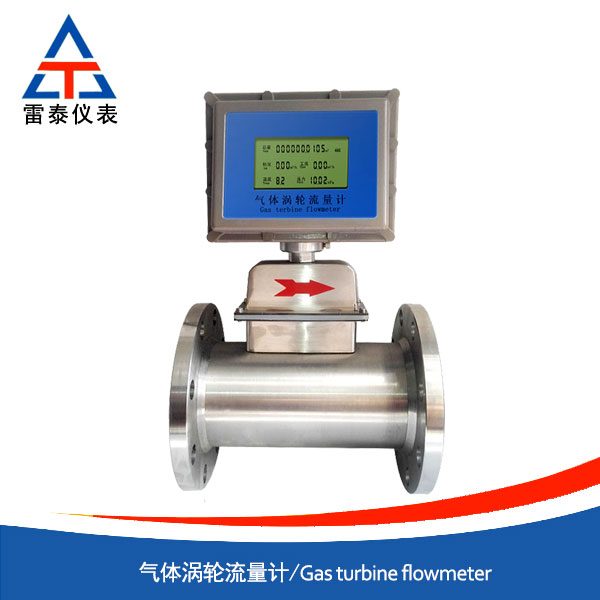

一、气体涡轮流量计概述

1、 Overview of gas turbine flowmeter

气体涡轮流量计采用先进的微处理技术,具有功能强,运算精度高、性能可靠等优点,主要技术指标达到国外同类产品的先进水平。是石油、化工、电力、冶金、工业与民用锅炉等燃气计量和城市天燃气、燃气调压站计量及燃气贸易计量的理想仪表。其工作原理是:当气体进入流量计时,先经过特殊的整流器加速,在流体的作用下,涡轮克服阻力力矩和磨擦力矩开始转动,当力矩达到平衡时,转速稳定,涡轮的转速与气体流量成正比,并经过旋转的发讯盘上的磁体周期性地改变传感器磁阻,从而传感器输出与流休成正比的脉冲信号。产品具有以下特点:

The gas turbine flowmeter adopts advanced micro processing technology, which has the advantages of strong function, high calculation accuracy and reliable performance. Its main technical indicators reach the advanced level of similar products abroad. It is an ideal instrument for gas metering in petroleum, chemical, electric power, metallurgy, industrial and civil boilers, urban natural gas, gas regulator station metering and gas trade metering. Its working principle is: when the gas enters the flow meter, it is accelerated by a special rectifier. Under the action of fluid, the turbine overcomes the resistance torque and friction torque and starts to rotate. When the torque reaches balance, the rotating speed of the turbine is proportional to the gas flow rate. The magnetic resistance of the sensor is changed periodically by the magnet on the rotating transmission disk, so that the sensor output and flow can be achieved It is proportional to the pulse signal. The product has the following characteristics:

1、采用德国进口仪表专用精密轴承,准确度高,稳定性好,范围度宽(20:1),小口径在一般使用条件下五年内可免于加油,大口径也只需偶尔加油,使用方便。

1. Special precision bearing imported from Germany is adopted, which has high accuracy, good stability and wide range (20:1). Small diameter can be free of oiling within five years under general service conditions, and large diameter only needs occasional oiling, so it is convenient to use.

2、精心设计的流道结构,避免了气流在轴承间的流动,提高了涡轮流量计的介质适应性。

2. The well-designed runner structure avoids the flow of air between bearings and improves the medium adaptability of turbine flowmeter.

3、独特的反推结构和密封结构设计,确保轴承长期可靠运行。

3. Unique reverse thrust structure and seal structure design ensure long-term and reliable operation of bearing.

4、采用磁阻元件来代替磁敏感线圈,既避免了磁吸力的存在,且提高了检测灵敏度,进一步降低了始动流量,并提高了产品的稳定性和可靠性。

4. The magnetic resistance element is used to replace the magnetic sensitive coil, which not only avoids the existence of magnetic attraction, but also improves the detection sensitivity, further reduces the starting flow, and improves the stability and reliability of the product.

5、独立式机芯设计,互换性好、维护方便。

5. Independent movement design, good interchangeability and convenient maintenance.

6、集温度、压力、流量传感器和智能流量积算仪于一体,可对被测气体温度、压力和压缩因子自动跟踪修正,直接计量气体的标准体积流量和总量。

6. Integrating temperature, pressure, flow sensor and intelligent flow totalizer, it can automatically track and correct the temperature, pressure and compression factor of the measured gas, and directly measure the standard volume flow and total volume of gas.

7、主要性能指标达到国际先进水平,符合ISO9951标准。

7. The main performance indexes have reached the international advanced level and conform to iso9951 standard.

8、采用微功耗高新技术,凭内外电源均可工作,内电池可连续使用五年以上。

8. It can work with internal and external power supply. The internal battery can be used continuously for more than five years.

9、功能强大,四种补偿方式、三种脉冲信号输出、三种历史数据记录方式、两种标准电流信号输出方式可选。

9. It has powerful functions. Four compensation modes, three pulse signal output modes, three historical data recording modes and two standard current signal output modes can be selected.

10、通过RS485接口组成网络通信系统,可方便实现自动化管理。RS485通信协议符合MODBUS规范。

10. The network communication system is composed of RS485 interface, which can realize automatic management conveniently. RS485 communication protocol conforms to MODBUS specification.

11、表头可180°随意旋转,安装方便。

11. The meter head can be rotated at 180 ° for easy installation.

二、气体涡轮流量计主要技术参数

2、 Main technical parameters of gas turbine flowmeter

2.1测量的介质

2.1 measuring medium

天然气、城市煤气等各种燃气、烷类及工业惰性气体。

Natural gas, city gas and other gas, alkane and industrial inert gas.

2.2使用条件

2.2 service conditions

◆环境温度:-30℃~+60℃; ◆介质温度:-20℃~+80℃;

Environment temperature: - 30 ℃ ~ + 60 ℃; medium temperature: - 20 ℃ ~ + 80 ℃;

◆大气压力:70kPa~106kPa; ◆相对湿度: 5%~95%。

Atmospheric pressure: 70kpa ~ 106kpa; relative humidity: 5% ~ 95%.

2.3电气性能指标

2.3 electrical performance index

2.3.1工作电源与功耗

2.3.1 working power supply and power consumption

a.外电源:+24VDC土15%,适用于4mA~20mA输出、脉冲输出、RS485等;

a. External power supply is + 24 VDC, 15%, suitable for 4mA ~ 20mA output, pulse output, RS485, etc;

b.内电源:1组3.6V锂电池,可连续使用五年以上。

b. Internal power supply: a set of 3.6V lithium batteries, which can be used continuously for more than five years.

2.4.2脉冲输出方式(LWQ型由设定选择以下三者之一)

2.4.2 pulse output mode (LWQ type, one of the following three is selected by setting)

a.工况脉冲信号,光电隔离放大输出,高电平幅度≥20V,低电平幅度≤1V。

a. Working condition pulse signal, photoelectric isolation amplifier output, high level amplitude ≥ 20V, low level amplitude ≤ 1V.

b.与标准休积流量成正比的频率信号,经光电隔离放大输出,高电平幅度≥20V,低电平幅度≤1V。

b. The frequency signal which is proportional to the standard discharge is output by photoelectric isolation amplification. The amplitude of high level is more than 20V and that of low level is less than 1V.

c.定标脉冲信号(与IC卡阀门控制器配套),高电平幅度≥2.8V,低电平幅度≤0.2V,单位脉冲代表体积量可设定范围:0.01m~10.00m。

c. Calibration pulse signal (matching with IC card valve controller), high level amplitude ≥ 2.8V, low level amplitude ≤ 0.2V, unit pulse representative volume can be set in the range of 0.01M ~ 10.00m.

2.4.3RS485通信(采用光电隔离RS485通信模块),可直接与上微机或二次仪表联网,远传显示当前数据和历史记录。

2.4.3 RS485 communication (photoelectric isolation RS485 communication module) can be directly connected with the upper computer or secondary instrument, and the current data and historical records can be displayed remotely.

2.4.4 4mA~20mA标准电流信号(采用光电隔离标准电流模块);两线制或三线制。

4.4.4 4 4 Ma ~ 20 mA standard current signal (using photoelectric isolation standard current module); two wire system or three wire system.

2.4.5控制信号输出

2.4.5 control signal output

a.上、下限报警信号(UP、LP):光电隔离开集电极(OC)输出,正常状态OC门截止,报警状态OC门导通,zui大负载电流50mA,工作电压+12VC~+24VDC。

a. Upper and lower limit alarm signals (up, LP): photoelectric isolation open collector (OC) output, OC gate off in normal state, OC gate on in alarm state, Zui large load current of 50mA, working voltage of + 12vc ~ + 24VDC.

b.关阀报警(BC)和电池欠压报警(BL)输出(IC卡控制器用);逻辑门电路输出,正常输出低电平,幅度≤0.2V;报警输出高电平,幅度≥2.8V,负载电阻≥100k0。

b. Valve closing alarm (BC) and battery under voltage alarm (BL) output (for IC card controller); logic gate circuit output, normal output low level, amplitude ≤ 0.2V; alarm output high level, amplitude ≥ 2.8V, load resistance ≥ 100k0.

2.5实时数据存贮功能

2.5 real time data storage function

a.启停记录:zui近的1200次启停时间、总量记录。

a. Start stop record: Zui's 1200 start stop time and total amount record.

b.日记录:zui近920天的日期、零点时刻的温度、压力、标准体积流量和总量记录。

b. Diary: Zui's 920 day date, temperature, pressure, standard volume flow rate and total volume record.

c.定时时间间隔记录:920 条定时时间间隔的8期时间、温度、压力、标准休积流量和总量记录。

c. Time interval record: 920 fixed time interval records of 8 periods of time, temperature, pressure, standard accumulated flow and total amount.

2.6防爆等级:隔爆型Exd II BT4。本安型Exia II CT4。

2.6 explosion proof grade: Flameproof Exd II BT4. Intrinsic safety Exia II cT4.

2.7防护等级:IP65

2.7 protection level: IP65

三、气体涡轮流量计选型

3、 Selection of gas turbine flowmeter

3.1适用范围

3.1 scope of application

a.要求流量范围度小于20:1(见表1),且对始动流量有较高要求的场合。

a. It is required that the flow range is less than 20:1 (see Table 1), and the starting flow has higher requirements.

b.不存在间隔时间短、流量波动幅度大的频繁流量波动。

b. There is no frequent flow fluctuation with short interval and large fluctuation range.

c.可测量天然气、城市煤气、压缩空气,氮气等。

c. It can measure natural gas, city gas, compressed air, nitrogen, etc.

3.2规格的确定

3.2 determination of specifications

依据标准状态下的供气流量范围及介质压力及温度计算工作状态下的流量范围(可參照旋进旋涡的选型)

According to the gas supply flow range under the standard state and the medium pressure and temperature, the flow range under the working state is calculated (refer to the selection of Precession Vortex)

3.3流量计的压力损失

3.3 pressure loss of flowmeter

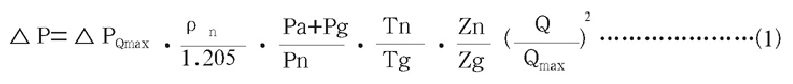

按以下公式(1)计算流量计在工作状态下zui大流量时的zui大压力损失△Pmax,流量计的zui大压力损失必须满足条件(2)方可保证流量计能正常使用,当压损失不满足公式(2)时,应选较大规格。

According to the following formula (1), calculate the Zui large pressure loss △ Pmax of the flowmeter under the working condition of Zui large flow rate. The Zui large pressure loss of the flowmeter must meet the condition (2) to ensure the normal use of the flowmeter. When the pressure loss does not meet the formula (2), the larger size should be selected.

a.压力损失可用下式计算

a. The pressure loss can be calculated by the following formula

式中:P:气体在标准状态(20℃,101.325KPa)下的密度;

Where: P: density of gas in standard state (20 ℃, 101.325kpa);

△Pomax:介质为常态干空气(密度为1.205kg/m)时zui大流量的压力损失(由表1查得);

Δ pomax: pressure loss of Zui at large flow rate when the medium is normal dry air (density is 1.205kg/m) (obtained from table 1);

Pa;当地大气压(kPa); Q:工况流量(m2/h);

PA; local atmospheric pressure (kPa); Q: flow under working condition (m2 / h);

Qmax:仪表最大工况流量(m3/h); Pg:介质表压力(kPa)。

Qmax: maximum working condition flow of instrument (m3 / h); PG: medium gauge pressure (kPa).

Pn:标准大气压(101.325kPa);Tn:标准状态下优良温度(293.15K);

PN: standard atmospheric pressure (101.325kpa); TN: excellent temperature under standard condition (293.15K);

Tg:介质工况条件下优良温度(273.15+t);其中t为介质工作温度(℃);

TG: excellent temperature under medium condition (273.15 + T); where t is medium working temperature (℃);

Zn、Zg:分别为标况和工况下的气体压缩系数。

Zn, ZG: gas compression coefficient under standard condition and working condition respectively.

b.压损应满足条件

b. The pressure loss should meet the conditions

P1-△Pmax≥Lmin...................(2)

P1-△Pmax≥Lmin...................(2)

式中:P1:在zui大流量时介质的zui低工作压力;

Where: P1: Zui low working pressure of medium at large Zui flow rate;

△Pmax:流量计在工作状态下zui大流量时的zui大压力损失;

Δ Pmax: Zui large pressure loss when the flowmeter is working with large flow rate;

PLmin:用(燃)气具使用所要求的zui低入口压力。

Plmin: low Zui inlet pressure required by gas appliance.

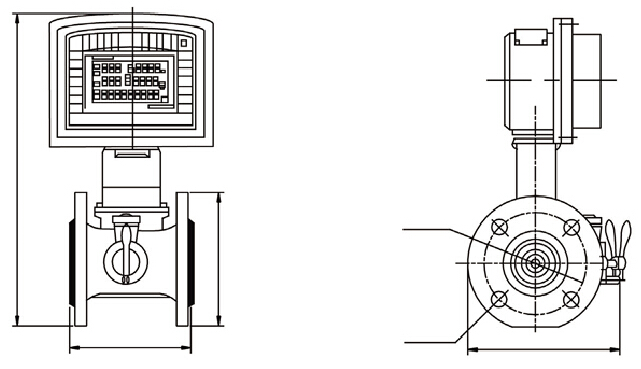

四、气体涡轮流量计外型尺寸

4、 External dimensions of gas turbine flowmeter

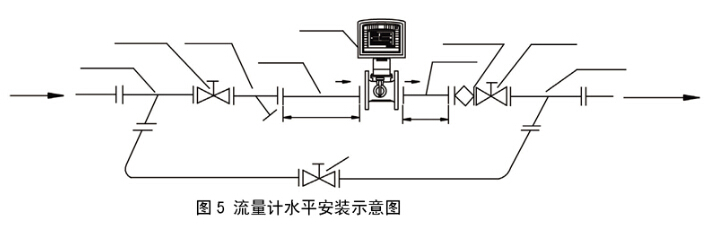

五、气体涡轮流量计安装及注意事项

5、 Installation and precautions of gas turbine flowmeter

a.为了便于维修,不影响流体正常输送,建议按下图所示设置旁通管道。

a. In order to facilitate maintenance and not affect the normal transportation of fluid, it is recommended to set up bypass pipeline as shown in the figure below.

b.为防止杂质进入流量计,必须安装过滤器,过滤器安装在流量计上游≥2DN处,本公司可提供配套过滤器。

b. In order to prevent impurities from entering the flowmeter, a filter must be installed. The filter should be installed at the upstream of the flowmeter ≥ 2DN. Our company can provide matching filter.

c.安装流量计前应将管道内的杂物、焊渣、粉尘等清理干净。

c. Before installing the flowmeter, the sundries, welding slag and dust in the pipeline should be cleaned up.

d.流量计具有性能优越的专用整流器,因此对直管段要求较低,但必须保证前直管段≥2DN,后直管段≥1DN。(对前直管段有弯管、异径管、调压阀等安装方式均适合)

d. The flowmeter has a special rectifier with superior performance, so the requirements for straight pipe section are lower, but the front straight pipe section must be ≥ 2DN, and the rear straight pipe section must be ≥ 1DN. (it is suitable for elbow, reducer and pressure regulating valve in front of straight pipe section)

e.流量计水平安装,并确保气流方向和流量计壳体上的方向标志-致。(须垂直安装时应在订货时注册,产品需做相应配置;安装使用时,气流方向应从上至下)

e. The flowmeter shall be installed horizontally, and the flow direction shall be consistent with the direction mark on the flowmeter shell. (for vertical installation, registration should be made at the time of ordering, and the product should be configured accordingly; when installing and using, the air flow direction should be from top to bottom)

f.流量计水平安装时,建议在流量计后直管段后安装钢制伸缩器(补偿器),伸缩器必须符合管道设计的公称通径和公称压力的要求。(伸缩器是作为管道应力的补偿及方便流量计的安装与拆卸)

f. When the flowmeter is installed horizontally, it is recommended to install a steel expansion joint (compensator) behind the straight pipe section behind the flowmeter. The expansion joint must meet the requirements of the nominal diameter and nominal pressure of the pipeline design. (the expansion device is used to compensate the pipeline stress and facilitate the installation and disassembly of the flowmeter)

g.流量计安装在室外使用时,建议加配防护罩,以免雨水浸入和烈8曝晒而影响流量计使用寿命。

g. When the flowmeter is installed outdoors, it is recommended to add a protective cover to avoid rain immersion and strong 8-exposure, which will affect the service life of the flowmeter.

h.流量计使用场合周围不能有强的外磁场干扰,流量计须可靠接地,但不得与强电系统地线共用。

h. There should be no strong external magnetic field interference around the flowmeter, and the flowmeter must be reliably grounded, but it should not be shared with the ground wire of strong current system.

六、气体涡轮流量计订货须知

6、 Instructions for ordering gas turbine flowmeter

6.1用户订购本产品时应根据管道公称通径、公称压力、流量范围、介质温度范围及环境条件选择合适的规格。

6.1 when ordering this product, the user should select the appropriate specification according to the nominal diameter, nominal pressure, flow range, medium temperature range and environmental conditions.

6.2流量计一般为基本型,带工况脉冲输出,若需其它附件及输出功能,请在订货时说明。

6.2 the flowmeter is generally of basic type with pulse output under working condition. If other accessories and output functions are required, please explain when ordering.

6.3用户在订货时,请按照下列格式详细正确填写。

6.3 when ordering, please fill in the details and correctly according to the following format.