Common problem

推荐资讯

免费咨询热线

+086-0517-86998608Common problem

一、浮标液位计安装调试

1、 Installation and commissioning of buoy level gauge

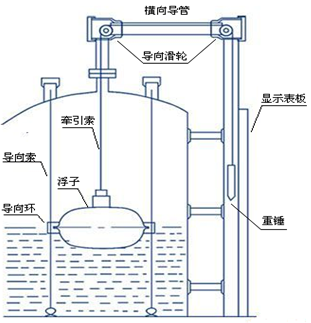

1、按照两个导向滑轮的间距,在容器上方开三个孔,分别焊接导向螺栓管和滑轮导管;在容器外侧焊接标尺支架,高度以保持两个导向滑轮水平为准

1. According to the distance between the two guide pulleys, three holes are drilled on the top of the container to weld the guide bolt tube and pulley guide tube respectively; the scale bracket is welded on the outside of the container, and the height shall be based on the level of the two guide pulleys

2、浮标液位计的调零

2. Zero adjustment of float level gauge

在浮标液位计安装时,罐内应还未有被测介质,浮标在罐内的底部时,重锤指针部分的红色尖头指示应指在标尺测量范围的顶部“零”值上,否则要调整钢丝长度。

When the buoy level gauge is installed, there is no medium to be measured in the tank. When the buoy is at the bottom of the tank, the red pointed indication of the pointer part of the heavy hammer should be on the top "zero" value of the scale measurement range, otherwise, the length of the steel wire should be adjusted.

3、浮标液位计量程调整

3. Range adjustment of buoy level gauge

浮标液位计在调好零位的基础上,再把浮标拉到容器的顶部或最大测量点上,重锤指针部分的红色尖头应指在标尺的底部位置上,即落在标尺最大量程点上。

On the basis of adjusting the zero position of the float level gauge, pull the buoy to the top of the container or the maximum measuring point. The red tip of the pointer part of the heavy hammer should point to the bottom position of the scale, that is, on the maximum measuring point of the scale.

二、浮标液位计安装使用和注意事项

2、 Installation, use and precautions of buoy level gauge

1、导向钢丝下支承焊接安装:

1. Welding and installation of lower support of guide wire:

在容器底部按照液位计浮子运动方向要求确定位置,焊接或铆接好固定导向钢丝下支承。如设备不具备焊接条件,可采用重锚固定方式固定导向钢丝下支承。如容器内液面波动不大,可不安装导向钢丝。

Determine the position at the bottom of the container according to the requirements of the float movement direction of the liquid level gauge, and weld or rivet the lower support of the fixed guide wire. If the equipment does not have welding conditions, heavy anchor can be used to fix the lower support of guide wire. If the liquid level in the container fluctuates little, the guide wire can not be installed.

2、导向钢丝的安装:

2. Installation of guide wire:

(1)用力使钢丝拉直,并固定在下支承上,注意不要使钢丝有弯曲或打结现象,以免影响浮子上下移动。

(1) Force the steel wire to straighten and fix it on the lower support. Pay attention not to make the steel wire bend or knot, so as to prevent the float from moving up and down.

(2)导向钢丝通过浮子的导向环,后穿入吊勾螺钉,把钢丝的终端固定并用导线夹头夹紧,并旋紧吊勾螺母,使其处于紧张状况,再将上螺母拼紧,以防松动,然后盖好封盖。

(2) The guide steel wire passes through the guide ring of the float and then goes through the hook screw. The end of the steel wire is fixed and clamped with the wire clamp. The hook nut is tightened to make it in tension. Then, the upper nut is tightened to prevent loosening, and then the cover is covered.

(3)两根导向钢丝要垂直地面,而且相互平行,保证两者之间距离与浮子的导向环的中心距一致

(3) The two guide wires should be vertical to the ground and parallel to each other to ensure that the distance between them is consistent with the center distance of the float guide ring

4、 标尺安装:

4. Scale installation:

标尺的长度是按用户在订货时所提供的测量范围而确定的,在安装时要求:

The length of the scale is determined according to the measurement range provided by the user when ordering. During installation, the following requirements are required:

(1)标尺的连结部分应做到平直、光滑、不应有凹凸现象,以免影响重锤指针的正常运行,或引起测量的误差。

(1) The connecting part of the scale shall be straight, smooth and free of concave convex phenomenon, so as to avoid affecting the normal operation of the heavy hammer pointer or causing measurement error.

(2)标尺应与贮罐内液面相垂直,不应有倾斜现象, 标尺安装的垂直度不能大于5°,以免造成重锤指针卡死,使测量失败。

(2) The ruler should be perpendicular to the liquid surface in the tank without inclination. The verticality of the scale installation should not be greater than 5 ° to avoid jamming of the heavy hammer pointer and failure of measurement.

(3)在焊接标尺脚架时,应尽量做到安装表面在同一平面上,安装孔在同上直线上,即做到确保标尺的刻度面及重锤指针两侧导向均要平直称为直线,使重锤指针在标尺槽中灵活升降。

(3) When welding the scale bracket, the installation surface should be on the same plane as far as possible, and the installation hole should be on the same straight line, that is to ensure that the scale surface of the scale and the guide of both sides of the heavy hammer pointer should be straight, which is called a straight line, so that the heavy hammer pointer can rise and fall flexibly in the scale groove.

5、 浮标连接钢丝及重锤指针的安装:

5. Installation of buoy connecting steel wire and heavy hammer pointer:

浮标与连接钢丝的一端用导线夹头夹紧固定,然后将连接钢丝的另一端装进事先安装好的两个导向滑轮盒内,并和重锤指针相连接,用导线夹头夹紧固定,最后调整各导向滑轮支架,使连接钢丝与水平垂直,使浮标在导向钢丝上活动灵活,有轻滑感、无卡死、扭曲、打结、打卷或损伤等现象。

The buoy is clamped and clamped with one end of the connecting steel wire, and then the other end of the connecting steel wire is installed in the two guide pulley boxes which are installed in advance, and is connected with the heavy hammer pointer, clamped and fixed with the wire clamping chuck. Finally, the guide pulley support is adjusted, so that the connecting steel wire is vertical to the horizontal, so that the buoy moves flexibly on the guide wire, and has a light sliding feeling, no stuck and twisted. Knotting, rolling or damage.

相关新闻

- Fault diagnosis and analysis of differential pressure transmitter in application 20-09-25

- Application and principle of bimetal thermometer 20-09-25

- How to install buoy level gauge 20-09-25

- Application of pH controller in acid alkali automatic control 20-09-25

- Cooling capacity measurement system of chilled water 20-09-25

- Advantage analysis of intelligent orifice flowmeter in actual measurement 20-07-29

- Problems encountered in operation of vortex flowmeter manufacturers 20-07-29

- Requirements for installation environment of vortex flowmeter 20-07-29