Flow meter

推荐资讯

免费咨询热线

+086-0517-86998608Flow meter

一、产品的技术优势:1、 Technical advantages of the product:1、专有流量数据模型算法;模糊理论控制温度、湿度算法;1. The algorithm of special flow data model, fuzzy control of temperature and humidity algorithm;2、高性能智能微处理器及模数、数模转换芯片;2. High performance intelligent microprocessor and a / ···

全国服务热线:+086-0517-86998608

在线咨询-

产品详情

一、产品的技术优势:

1、 Technical advantages of the product:

1、专有流量数据模型算法;模糊理论控制温度、湿度算法;

1. The algorithm of special flow data model, fuzzy control of temperature and humidity algorithm;

2、高性能智能微处理器及模数、数模转换芯片;

2. High performance intelligent microprocessor and a / D and D / a conversion chip;

3、宽量程比100:1;大口径,低流速,压损可忽略;

3. Wide range ratio 100:1; large diameter, low flow rate, pressure loss can be ignored;

4、直接测量质量流量,无须温压补偿;

4. Direct measurement of mass flow without temperature and pressure compensation;

5、低流速测量非常灵敏;

5. Low velocity measurement is very sensitive;

6、设计、选型方便,安装、使用简便;

6. It is convenient for design and selection, easy to install and use;

7、适合各类单一或混合气体流量测量。

7. It is suitable for all kinds of single or mixed gas flow measurement.

二、产品特点:

2、 Product features:

1、采用稳定性极高的专利技术铂RTD传感器

1. Platinum RTD sensor with high stability and patent technology

2、采用享有专有技术”平衡结构封装”,介质温度自补偿

2. Using proprietary technology "balanced structure package", self compensation of medium temperature

3、专有算法,可实现高线性、高重复性、高精度

3. Proprietary algorithm can achieve high linearity, high repeatability and high precision

4、量程比宽100:1,可据用户要求可拓展

4. The range ratio is 100:1, which can be expanded according to the requirements of users

5、可实现大管径小流量测量,最小流量可测低至零,分辨率0.001m/s

5. The minimum flow rate can be measured as low as zero, and the resolution is 0.001m/s

6、无可动部件、振动影响可忽略

6. No moving parts and negligible vibration effect

7、直管段要求不高1-2D

7. The requirement of straight pipe section is not high 1-2D

8、与介质的温度、压力无关

8. It has nothing to do with the temperature and pressure of the medium

9、专有高温算法,介质温度可达+510℃,

9. Proprietary high temperature algorithm, medium temperature up to + 510 ℃,

10、采用高湿算法,实现高精度测量

10. High humidity algorithm is used to realize high precision measurement

11、对流量信号键入12点动态修正,内置10点修正

11. Input 12 points dynamic correction for flow signal, and built-in 10 points correction

12、在线动态校正电流/电压输出

12. On line dynamic correction of current / voltage output

13、对粉尘等小颗粒不敏感

13. It is not sensitive to small particles such as dust

14、在线不断流装卸,维护方便

14. Online loading and unloading without interruption of flow, convenient maintenance

三、应用场合:

3、 Applications:

1、公用工程---电﹑气﹑ 水处理的监控

1. Public works monitoring of power, gas and water treatment

管道的气体;通用系统;沼气;煤气;天然气;液化气;锅炉预热空气

Pipeline gas; general system; biogas; gas; natural gas; liquefied gas; boiler preheating air

2、石油与天然气工业

2. Oil and gas industry

能量交换;填井气回收; 燃气计量;气体质量分析;泄漏气测试;天然气测量;火炬气的监控

Energy exchange; well filling gas recovery; gas metering; gas quality analysis; leakage gas test; natural gas measurement; torch gas monitoring

3、电力行业

3. Electric power industry

燃料系统中气体分配过程中的气体测量;锅炉及辅助系统中各种气体的测量;燃气炉中气体测量;氢气测量;电厂高炉的一次风、二次风的测量

Gas measurement in the process of gas distribution in fuel system; gas measurement in boiler and auxiliary system; gas measurement in gas furnace; hydrogen measurement; primary air and secondary air measurement of blast furnace in power plant

4、化学行业

4. Chemical industry

烟气循环监测;采样系统中气体流量计量;引风机的气体流量计量;化肥厂氨气测量 ;电池工厂各种气体流量测量

Flue gas circulation monitoring; gas flow measurement in sampling system; gas flow measurement of induced draft fan; ammonia measurement in fertilizer plant; various gas flow measurement in battery plant

5、冶金行业

5. Metallurgical Industry

钢铁厂加气测量;炼铁厂高炉煤气的测量;焦化厂焦炉煤气的测量;轧钢厂加热炉燃气(高炉煤气、焦化煤气、天然气等)的测量控制;热处理淬火炉等的氢、氧、氮等气体的控制

Gas filling measurement of iron and steel plant; measurement of blast furnace gas of iron making plant; measurement of coke oven gas of coking plant; measurement control of heating furnace gas (blast furnace gas, coking gas, natural gas, etc.) in rolling plant; control of hydrogen, oxygen, nitrogen and other gases in heat treatment quenching furnace

6、纸浆与造纸行业

6. Pulp and paper industry

废水处理系统中气体的测量;烟道流量监控;锅炉回收二次/三次空气;锅炉的燃气和空气送风测量

Gas measurement in wastewater treatment system; flue flow monitoring; boiler recovery of secondary / tertiary air; measurement of boiler gas and air supply air

7、食品及医药行业

7. Food and pharmaceutical industry

加工操作中新鲜空气的加入;啤酒厂中的二氧化碳处理;瓶子消毒器中的热空气的流量;热氧化过程中气体流量测量;通风系统;锅炉进气﹑废气﹑过程控制

Fresh air addition in processing operation; carbon dioxide treatment in breweries; hot air flow in bottle sterilizer; gas flow measurement in thermal oxidation process; ventilation system; boiler intake, exhaust gas, process control

8、环保

8. Environmental protection

沼气利用过程中的气体测量;氯气处理过程中氯气气体测量;污水处理过程中曝气池的气体测量;烟筒烟道排气监测SO2和NOX的排量

Gas measurement in the process of biogas utilization; chlorine gas measurement in chlorine treatment process; gas measurement in aeration tank during sewage treatment; flue gas emission monitoring of SO2 and NOx

9、其他行业

9. Other industries

工厂压缩空气测量;煤粉燃烧过程粉/气配比控制燃料;水泥工业竖式磨粉机排放热气流量控制

The results show that: the measurement of compressed air in factory; the control of pulverized coal / gas ratio in the process of pulverized coal combustion; the control of hot gas discharge from Vertical Pulverizer in cement industry

四、性能指标:

4、 Performance index:

1、测量范围:0.5—100Nm/s (20℃,101.33KPa)

1. Measurement range: 0.5-100nm / S (20 ℃, 101.33kpa)

2、准确度: ±1%的读数 ±0.5%满量程

2. Accuracy: ± 1% of reading ± 0.5% of full scale

3、量程比:通常100:1(取决于标定流量的范围)

3. Range ratio: usually 100:1 (depending on the range of calibrated flow)

4、管径范围: 15mm~6000mm

4. Pipe diameter range: 15mm ~ 6000mm

5、应用范围: 适合各类单一或混合气体。含尘、含沙、含湿气、各种腐蚀性气体

5. Application range: suitable for all kinds of single or mixed gases. It contains dust, sand, moisture and various corrosive gases

6、环境温度范围: -40℃~+85℃(无显示); -30℃~+70℃(有显示); 湿度小于90%RH

6. Ambient temperature range: - 40 ℃ - + 85 ℃ (no display); - 30 ℃ - + 70 ℃ (with display); humidity less than 90% RH

7、介质温度范围: -40℃~+100℃;-40℃~+200℃; -40℃~+450℃;-40℃~+510℃

7. Medium temperature range: - 40 ℃ - + 100 ℃; - 40 ℃ - + 200 ℃; - 40 ℃ - + 450 ℃; - 40 ℃ - + 510 ℃

8、传感器直径:ф3、ф2.5

8. Sensor diameter: ф 3, ф 2.5

9、插入式传感器探杆直径:ф19(标准)、ф16、ф12

9. Probe rod diameter of plug-in sensor: ф 19 (standard), ф 16, ф 12

10、传感器材质:316不锈钢、哈氏合金、钛

10. Sensor material: 316 stainless steel, Hastelloy, titanium

11、探杆材质(保护套): 316不锈钢(标准)、哈氏合金

11. Probe rod material (protective sleeve): 316 stainless steel (standard), Hastelloy

12、双向测量介质流量

12. Two way measurement of medium flow

13、模拟量输出:流量:4-20mADC, 温度:4-20mADC, 最大负载:1000Ω

13. Analog output: flow: 4-20madc, temperature: 4-20madc, maximum load: 1000 Ω

14、累积脉冲量输出

14. Cumulative impulse output

15、键入12段非线性修正,内置10段非线性修正

15. Type in 12 segments of non-linear correction, built-in 10 segment nonlinear correction

16、通讯:串口输出RS232/RS485

16. Communication: serial output RS232 / RS485

17、供电电源:24VDC/600mA;220VAC/2W;110VAC/3W

17. Power supply: 24 VDC / 600 Ma; 220 VAC / 2 W; 110 VAC / 3 W

18、报警:1-2路继电器输出、5A/220V、5A/30VDC、键入设定??

18. Alarm: 1-2 way relay output, 5A / 220V, 5A / 30VDC, input setting??

19、大屏幕LCD显示:七位瞬时流量,八位累积流量

19. 8-bit LCD display for instantaneous flow

20、过程压力:1.6Mpa(最大20MPa)

20. Process pressure: 1.6Mpa (maximum 20MPa)

21、安装工艺形式:插入式(卡套、卡套+球阀、法兰连接)适用于DN80以上的管道安装,管道式(法兰、螺纹连接)适用于DN15以上的管道安装。

21. Installation process form: plug in type (ferrule, ferrule + ball valve, flange connection) is suitable for pipe installation above DN80, and pipeline type (flange and thread connection) is suitable for pipe installation above DN 15.

22、防爆等级:本安型(iaⅡCT5)、隔爆型(ExdⅡCT4)

22. Explosion proof grade: intrinsically safe (IA Ⅱ CT5), flameproof (Exd Ⅱ cT4)

23、防护等级:IP65

23. Protection grade: IP65

热式气体质量流量计的安装

Installation of thermal gas mass flowmeter

1、插入式仪表安装

1. Plug in instrument installation

将仪表传感器杆上的止退螺母松开,使腔式连接螺母能够沿传感器杆滑向传感器护套,使护套完全缩入腔式连接螺母中。

Loosen the check nut on the sensor rod of the instrument, so that the cavity connecting nut can slide along the sensor rod to the sensor sheath, so that the sheath is fully retracted into the cavity connecting nut.

将腔式连接螺母紧固于专用球阀上(需在它们之间加装密封垫)

Fasten the cavity type connecting nut to the special ball valve (need to add sealing gasket between them)

打开专用球阀,将传感器杆压入管道,直至止退螺母能够与腔式连接螺母锁紧。

Open the special ball valve and press the sensor rod into the pipe until the retaining nut can be locked with the cavity connecting nut.

转动传感器杆,使标记点能与介质流动方向同向,锁紧止退螺母。更改显示屏方向。

Turn the sensor rod so that the mark point can be in the same direction as the flow direction of the medium, and lock the retaining nut. Change the display orientation.

如果显示屏的方向不能满足现场显示角度的要求,可以更改显示屏的方向。显示表头可在水平6个方向上转动,更改方法是:切断电源,打开转换器前盖,断开传感器与转换器连线(两组共4根或3组6根,组与组之间不能互换,同一组两根线可互换),松开表头法兰(旋掉6颗M6的内六角螺栓),此时可转动转换器(不要让转换器跌落),直到观测方便,重新固定法兰,并连接传感器与转换器连线,盖紧转换器前盖,接通电源。

If the direction of the display screen cannot meet the requirements of the field display angle, the direction of the display screen can be changed. The indicator can be rotated in six horizontal directions. The change method is as follows: cut off the power supply, open the front cover of the converter, disconnect the connecting wire between the sensor and the converter (there are 4 in two groups or 6 in 3 groups, which cannot be interchanged between groups, and two wires in the same group can be interchanged), loosen the flange of the meter head (screw off 6 M6 hexagon bolts), and then turn the converter (do not let the converter fall) until It is convenient to observe. Fix the flange again, connect the sensor to the converter, close the front cover of the converter, and connect the power supply.

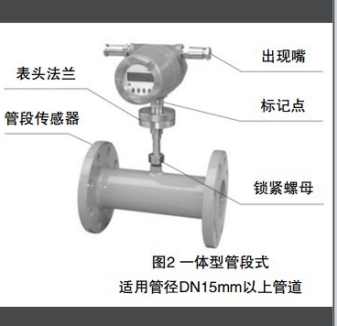

2、管段式仪表安装

2. Installation of pipe section instrument

确认管段的连接方式(法兰连接或螺纹连接)。管段式仪表已在出厂时把传感器装配在专用管段上,用户只需把管段再装配到现场,因此相对现场插入式仪表的安装要简单。首先按照现场插入式仪表安装的第1部选择安装点。然后按照管段式传感器的尺寸切割管道、安装配对法兰或螺纹。后用螺栓安装管段仪表,安装时要保证仪表的标记方向和介质流体方向同向,并且显示平面要垂直于水平面,管道轴心线要平行于水平面,误差不能超过±5度

Confirm the connection mode of pipe section (flange connection or thread connection). The sensor has been assembled on the special pipe section when the pipe section instrument is delivered from the factory. The user only needs to assemble the pipe section to the site again, so the installation of the on-site plug-in instrument is relatively simple. First, select the installation point according to the first part of the field plug-in instrument installation. Then cut the pipe and install the mating flange or thread according to the size of the segment sensor. Then install the pipe section instrument with bolts. During installation, ensure that the marking direction of the instrument is in the same direction as the medium fluid direction, and the display plane shall be vertical to the horizontal plane, and the pipeline axis line shall be parallel to the horizontal plane, and the error shall not exceed ± 5 degrees