Flow meter

推荐资讯

免费咨询热线

+086-0517-86998608Flow meter

金属管浮子流量计概述Overview of metal tube rotameter1、金属管浮子流量计采用可变面积式测量原理,适用于测量液体,气体。全金属结构,有指示型、电远传型、耐腐型、高压型、夹套型、防爆型。具有0-10mA,4-20mA的标准模拟量信号输出和现场指示。累积,数字通讯,现场修改测量参数,不同的供电方式功能,带有磁性过滤器和特殊规格品种。广泛应用于,石油、化工、发电、制药、食品、水处理等。复杂,恶劣环境条件,及各种介质条件的流量测量过程中。 &nbs···

全国服务热线:+086-0517-86998608

在线咨询-

产品详情

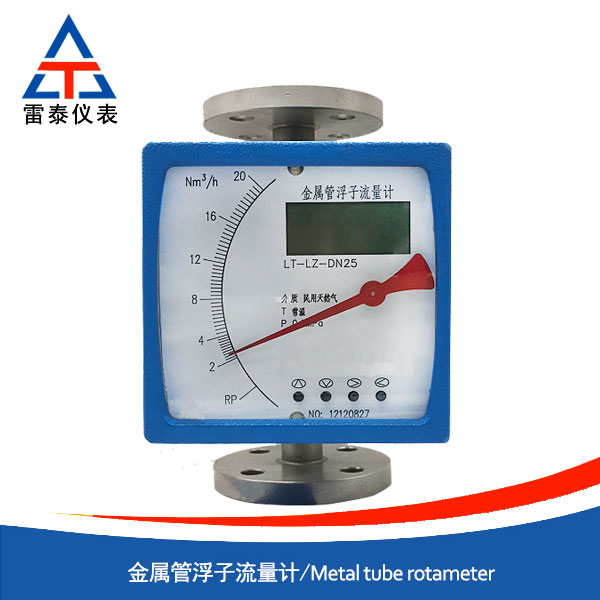

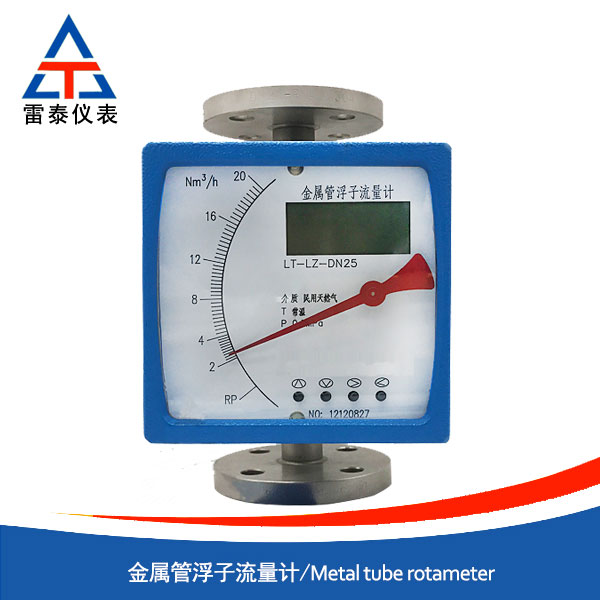

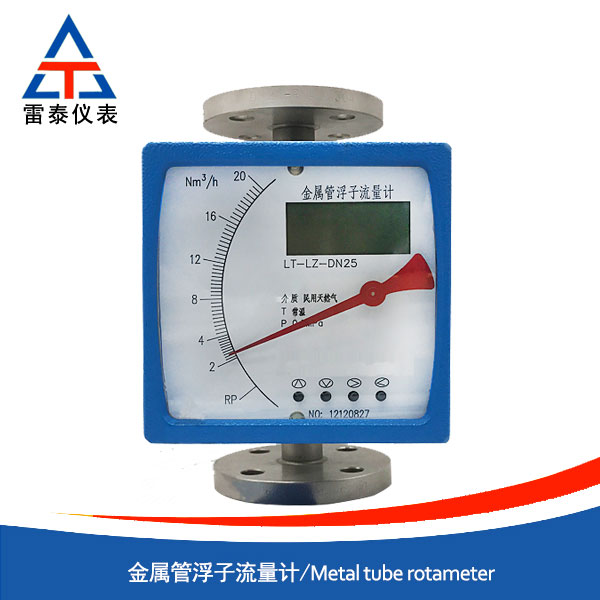

金属管浮子流量计概述

Overview of metal tube rotameter

1、金属管浮子流量计采用可变面积式测量原理,适用于测量液体,气体。全金属结构,有指示型、电远传型、耐腐型、高压型、夹套型、防爆型。具有0-10mA,4-20mA的标准模拟量信号输出和现场指示。累积,数字通讯,现场修改测量参数,不同的供电方式功能,带有磁性过滤器和特殊规格品种。广泛应用于,石油、化工、发电、制药、食品、水处理等。复杂,恶劣环境条件,及各种介质条件的流量测量过程中。 2、金属管浮子流量计是工业自动化过程控制中常用的一种变面积流量测量仪表。它具有体积小,检测范围大,使用方便等特点。它可用来测量液体、气体以及蒸汽的流量,特别适宜低流速小流量的介质流量测量。

1. Metal tube rotameter adopts variable area measurement principle, which is suitable for measuring liquid and gas. All metal structure, including indicator type, electric remote transmission type, corrosion-resistant type, high-voltage type, jacket type, explosion-proof type. It has 0-10mA, 4-20mA standard analog signal output and field indication. Accumulation, digital communication, on-site modification of measurement parameters, different power supply mode functions, with magnetic filter and special specifications. Widely used in petroleum, chemical, power generation, pharmaceutical, food, water treatment and so on. Complex, harsh environmental conditions, and various media conditions in the flow measurement process. 2. Metal tube rotameter is a kind of variable area flow meter commonly used in industrial automation process control. It has the characteristics of small volume, large detection range and easy to use. It can be used to measure the flow rate of liquid, gas and steam, especially suitable for medium flow measurement with low flow rate and small flow rate.

金属管浮子流量计测量部分特点

Characteristics of metal tube rotameter

1、坚固的全金属结构设计型浮子流量计

1. Solid all metal structure design Rotameter

2、采用独立概念设计的测量管指示器

2. Measuring tube indicator with independent concept design

3、可选择不锈钢、哈氏合金、钛材、PTFE材料测量系统

3. Stainless steel, Hastelloy, titanium, PTFE material measurement system can be selected

4、低压力损失设计

4. Low pressure loss design

5、短行程、小型结构设计、仪表总高度250

5. Short stroke, small structure design, total height of instrument 250

6、磁性耦合结构确保数据传输、信号更加稳定

6. Magnetic coupling structure ensures data transmission and signal stability

7、保温或伴热夹套

7. Insulation or heat tracing jacket

8、垂直、水平、各种安装方式更适合不同使用场合

8. Vertical, horizontal and various installation methods are more suitable for different occasions

9、适用于小口径和低流速介质流量测量

9. It is suitable for small diameter and low velocity medium flow measurement

10、工作可靠,维护量小,寿命长

10. Reliable operation, small maintenance and long service life

11、对于直管段要求不高

11. The requirements for straight pipe section are not high

12、较宽的流量比10:1

12. Wide flow ratio 10:1

13、双行大液晶显示,可选现场瞬时/累计流量显示,可带背光

13. Double line large LCD display, optional on-site instantaneous / cumulative flow display, with backlight

14、单轴灵敏指示

14. Single axis sensitive indication

15、非接触磁耦合传动

15. Contactless magnetic coupling drive

16、全金属结构,适于高温、高压和强腐蚀性介质

16. All metal structure, suitable for high temperature, high pressure and strong corrosive medium

17、可用于易燃、易爆危险场合

17. It can be used in inflammable and explosive dangerous places

18、选二线制、电池、交流供电方式

18. Two wire system, battery and AC power supply mode

19、多参数标定功能

19. Multi parameter calibration function

20、带有数据恢复,数据备份及掉电保护功能

20. With data recovery, data backup and power down protection functions

金属管浮子流量计主要技术参数

Main technical parameters of metal tube rotameter

◇测量范围:水(20℃)1-200000 l/h 空气(20℃,0.1013MPa)0.03-4000m3/h;参见流量表,特殊流量可订制

Measurement range: water (20 ℃) 1-200000 L / h, air (20 ℃, 0.1013mpa) 0.03-4000m3/h; refer to flow meter, special flow can be customized

◇量 程 比:标准型10:1

Range ratio: Standard 10:1

◇精 度:标准型1.0级;特殊型0.5级

Accuracy: standard type 1.0; special type 0.5

◇压力等级:标准型:DN15-DN50 4.0MPa DN80-DN200 1.6MPa

Pressure rating: Standard Type: DN 15-dn50 4.0Mpa dn80-dn200 1.6Mpa

特殊型:DN15-DN50 25MPa DN80-DN200 16MPa

Special type: DN 15-dn50 25MPa dn80-dn200 16MPa

夹套的压力等级为1.6MPa;

The pressure grade of jacket is 1.6Mpa;

特殊型在选型和订货前应与工厂协商

Special type should be negotiated with factory before type selection and order

◇压力损失:7kPa-70kP

Pressure loss: 7kpa-70kp

◇介质温度:标准型:-80℃-+200℃:PTFE:0℃-85度

Medium temperature: Standard Type: - 80 ℃ - + 200 ℃: PTFE: 0 ℃ - 85 ℃

高温型:*高可达300℃

High temperature type: * up to 300 ℃

◇介质粘度:DN15:η<5mPa.s(F15.1-F15.3)/η<30mPa.s(F15.4-F15.8)

Medium viscosity: DN 15: η < 5MPa. S (f15.1-f15.3) / η < 30MPa. S (f15.4-f15.8)

DN25:η<250mPFa.s

DN25:η<250mPFa.s

DN50-DN150:η<300mPa.s

DN50-DN150:η<300mPa.s

◇环境温度:指针型-40℃-+120℃

Environment temperature: pointer type - 40 ℃ - + 120 ℃

◇连接形式:标准型:DIN2501标准法兰

Connection type: Standard Type: din2501 standard flange

特殊型:由用户指定的任意标准法兰或螺纹

Special type: any standard flange or thread specified by the user

◇电缆接口:M20*1.5

Cable interface: M20 * 1.5

◇供电电源:标准型:24VDC二线制4-20mA(10.8VDC-36VDC)

Power supply: Standard Type: 24 VDC two wire system 4-20mA (10.8vdc-36vdc)

◇报警输出:上限或下限瞬时流量报警,集电极开路输出(*大100mA@30VDC内部阻抗100欧)

Alarm output: upper or lower limit instantaneous flow alarm, collector open circuit output (*) 100mA@30VDC Internal impedance 100 Ω)

继电器输出(触点容量1A@30VDC或0.25A@250VAC或0.5A@125VAC)

Relay output (contact capacity 1A@30VDC Or 0 25A@250VAC Or 0 5A@125VAC )

◇脉冲输出:累积脉冲输出,*小间隔50毫秒

Pulse output: cumulative pulse output, * interval 50 ms

◇液晶显示:瞬时流量显示数值范围:0-50000

Liquid crystal display: instantaneous flow display value range: 0-50000

累计流量显示数值范围:0-99999999(可带小数点)

Display value range of cumulative flow: 0-9999999 (with decimal point)

◇防护等级:IP65

Protection level: IP65

◇防爆标志:本安型iaⅡCT5;

Explosion proof sign: intrinsically safe IA Ⅱ CT5;

隔爆型dⅡBT6 SYTFLZ-250金属管浮子流量计测量范围

Measuring range of flameproof D Ⅱ BT6 sytflz-250 metal tube rotameter

| Corrosion resistant diameterDN(mm) | Common diameterDN(mm) | Flow range | *Large pressure loss | ||

| atmosphere m3/h 20℃0.101325 MPa | water L/h 20℃ | atmosphere (kPa) | water (kPa) | ||

| 15 | 15 | 0.07~0.7 | 2.5~25 | 7.1 | 6.5 |

| 0.11~1.1 | 4.0~40 | 7.2 | 6.5 | ||

| 0.18~1.8 | 6.0~60 | 7.3 | 6.6 | ||

| 0.28~2.8 | 10~100 | 7.5 | 6.6 | ||

| 0.40~4.0 | 16~160 | 8.0 | 6.8 | ||

| 0.70~7.0 | 25~250 | 10.8 | 7.2 | ||

| 1.00~10 | 40~400 | 10 | 8.6 | ||

| 25 | 1.60~16 | 60~600 | 14 | 11.1 | |

| 25 | 3.00~30 | 100~1000 | 7.7 | 7 | |

| 4.50~45 | 160~1600 | 8.8 | 8 | ||

| 7.00~70 | 250~2500 | 12 | 10.8 | ||

| 50 | 11~110 | 400~4000 | 19 | 15.8 | |

| 50 | 18~180 | 600~6000 | 8.6 | 8.1 | |

| 25~250 | 1000~10000 | 10.4 | 11 | ||

| 80 | 40~400 | 1600~16000 | 15.6 | 17 | |

| 80 | 75~750 | 2500~25000 | 8.1 | ||

| 100 | 100~1000 | 4000~40000 | 9.5 | ||

| 100 | 150~1500 | 6000~60000 | 10 | ||

| 150 | 125 | 8000~80000 | |||

| 100000~1000000 | |||||

| 150 | 15000~150000 | ||||

转换指示器转换器实际上是将锥管内浮子的高度转换成所对应的体积流量的刻度。 从输出信号来分:有就地显示型和远传信号输出型:就地显示型:由就地指示器中的随动磁钢与浮子内磁钢耦合,而发生转动,同时电动指针通过刻度盘指示出此时流量

The conversion indicator converter actually converts the height of the float in the cone tube into the corresponding volume flow scale. From the output signal: there are local display type and remote signal output type: local display type: the servo magnetic steel in the local indicator is coupled with the magnetic steel in the float to rotate, and the electric pointer indicates the flow rate at this time through the dial

式中α 仪表的流量系数,因浮子形状而异;

The flow coefficient of α meter varies with the shape of float;

ε 被测流体为气体时气体膨胀系数,通常由于此系数校正量很小而被忽略,且通过校验已将它包括在流量系数内,如为液体则ε= 1

When the measured fluid is a gas, the gas expansion coefficient is usually ignored because of its small correction, and it has been included in the flow coefficient through verification. If it is a liquid, then ε = 1

△F 流通环形面积,m2 ;

Δ f circulation annular area, m2;

g 当地重力加速度,m/s2;

G local gravity acceleration, M / S2;

Vf 浮子体积,如有延伸体亦应包括,m3;

VF float volume, if there is an extension, m3;

ρf 浮子材料密度,kg/m3;

ρ f float material density, kg / m3;

ρ 被测流体密度,如为气体是在浮子上游横截面上的密度,kg/m3;

ρ the density of the fluid to be measured, in case of gas, the density on the cross section upstream of the float, kg / m3;

Ff 浮子工作直径(*大直径)处的横截面,m2;

F cross section at the working diameter of the float (* large diameter), m2;

Gf 浮子重量,kg。

GF float weight, kg.

流通环形面积与浮子高度之间的关系如式(3)所示,当结构设计已定,则d、β为常量。

The relationship between the circulating annular area and the float height is shown in equation (3). When the structural design has been determined, then D and β are constants.

式中有h的二次项,一般不能忽略此非线性关系,只有在圆锥角很小时,才可视为近似线性。

If there is a quadratic term of H in the formula, the nonlinear relation can not be ignored. Only when the cone angle is very small, can it be regarded as approximately linear.

式中d 浮子*大直径(即工作直径),m;

Where d float * large diameter (i.e. working diameter), m;

h 浮子从锥管内径等于从浮子*大直径处上升高度,m;

H. the inner diameter of the float from the cone tube is equal to the rising height from the float * large diameter, m;

β 锥管的圆锥角;

The cone angle of β - cone tube;

a、b 为常数

a. B is a constant

从(1),(2),(3)公式可知,在一定的条件下,浮子在锥管内的高度与体积流量有一定的比例对应关系。读出浮子的高度,就可以知道相对应的体积流量,再通过转换器,将浮子的高度转换成所对应的体积流量所对应的刻度,这就是金属管浮子流量计的检测原理。

According to the formula (1), (2), (3), under certain conditions, the height of the float in the cone tube has a certain proportion corresponding to the volume flow. Read the height of the float, you can know the corresponding volume flow, and then through the converter, the height of the float will be converted into the corresponding volume flow corresponding to the scale, this is the detection principle of metal tube rotameter.

智能远传型,由智能型指示器中的随动磁钢与浮子内磁钢耦合,而发生转动,同时带动传感磁钢及指针,通过一个磁传感器将磁场变化转化成电信号,经A/D转换,数字滤波,微处理器处理,D/A输出,LCD液晶显示,来显示出瞬时流量及累积流量大小。(如下图所示)

Intelligent remote transmission type, by the intelligent indicator of the magnetic steel and the magnetic steel in the float coupling, and rotation, while driving the sensing magnetic steel and pointer, through a magnetic sensor to change the magnetic field into electrical signals, through a / D conversion, digital filtering, microprocessor processing, D / a output, LCD display, to display the instantaneous flow and cumulative flow. (as shown in the figure below)

金属管浮子流量计的口径、浮子号及刻度的计算

Calculation of diameter, float number and scale of metal tube rotameter

1、计算方法

1. Calculation method

(1) 根据用户给出的数据,选择适当的公式计算相应标校介质的流量Qs:

(1) According to the data given by the user, select the appropriate formula to calculate the flow rate QS of the corresponding calibration medium

其中:Qs-标校介质(水或空气)在标准状态下(20℃,0.1013Mpa)的流量

Where: QS is the flow rate of calibration medium (water or air) in standard state (20 ℃, 0.1013mpa)

Q-用户介质流量 K-修正系数

Q-user medium flow K-correction coefficient

(2)根据计算得到的 Qs值,查流量表来确定选用的浮子号及测量管的口径(流量表中的数值都是水或空气在标准状态下的流量值)

(2) According to the calculated QS value, check the flow meter to determine the selected float number and the diameter of the measuring tube (the values in the flow meter are the flow values of water or air in the standard state)

(3)确定测量管口径和浮子号后,建议用下式确定被测介质流量刻度的上限值Q:

(3) After determining the diameter of the measuring tube and the float number, it is suggested to use the following formula to determine the upper limit value Q of the measured medium flow scale:

其中:Qi查流量表中选取某一浮子号对应的水或空气流量的*大值。

Where: Qi check the flow meter and select the * large value of water or air flow corresponding to a float number.

(4)由于计算中没有考虑粘度的修正,有可能与工厂计算的结果产生差异。

(4) Because the correction of viscosity is not considered in the calculation, it may be different from the results calculated by the factory.

2、修正系数K的确定

2. Determination of correction coefficient K

(1)对于液体介质

(1) For liquid media

a、如果Q是液体体积流量则用下式计算K:

a. If q is the volume flow rate of liquid, K is calculated by the following formula:

b、如果Q是液体质量流量则用下式计算K:

b. If q is the mass flow rate of liquid, K is calculated by the following formula:

其中:ρf:所选浮子密度(g/cm3)

Where: ρ F: density of selected float (g / cm3)

不锈钢浮子密度为7.8

The density of stainless steel float is 7.8

聚四氟乙烯浮子(PTFE)密度为3.4

The density of PTFE float is 3.4

镍基合金(Hastelloy)密度为8.3

The density of Hastelloy was 8.3

ρ:被测介质的密度

ρ: Density of measured medium

(2)对于气体体介质

(2) For gaseous media

a、如果Q是标准状态下(20℃,0.1013Mpa)气体的体积流量,则用下式计算K:

a. If q is the volume flow rate of gas in standard state (20 ℃, 0.1013mpa), then K can be calculated by the following formula:

b、如果Q是操作状态下气体的体积流量,则用下式计算K:

b. If q is the volume flow rate of gas in the operating state, K is calculated by the following formula:

c、如果Q是气体的质量流量,则用下式计算K:

c. If q is the mass flow rate of gas, K is calculated by the following formula:

在以上各式中:

In the above formulas:

ρ: 被测介质的密度:被测气体介质在20℃,0.1013MPa状态下密度(kg/m3)

ρ: Density of the measured medium: the density of the measured gas medium at 20 ℃, 0.1013mpa (kg / m3)

P:被测气体介质的优良压力(MPa)

P: Excellent pressure of measured gas medium (MPA)

T:被测气体介质的优良温度(K)

T: Excellent temperature of gas medium to be measured (k)

ρ0:空气在20℃,0.1013MPa情况下密度(1.205kg/m3)

ρ 0: air density at 20 ℃, 0.1013mpa (1.205kg / m3)

P 0:标校介质的优良压力(0.1013MPa)

P 0: excellent pressure of calibration medium (0.1013mpa)

T 0:标校介质的优良温度(293.15K)

T 0: excellent temperature of calibration medium (293.15K)

d、辅助密度换算公式

d. Auxiliary density conversion formula

其中:ρst: 被测气体介质在标准状态下密度(Kg/m3)

Where: ρ ST: density of gas medium under standard state (kg / m3)

ρt: 被测气体介质在操作状态下密度(Kg/m3)

ρ T: density of measured gas medium under operating state (kg / m3)

Tt: 被测气体介质在操作状态下优良温度(K)

TT: excellent temperature (k) of gas medium under operation

Pt:被测气体介质在操作状态下优良压力(MPa)

Pt: excellent pressure of measured gas medium under operating state (MPA)

p0:被测气体介质在标准状态下优良压力(MPa)

P0: excellent pressure of gas medium under standard state (MPA)

T0:被测气体介质在操作状态下优良温度(K)

T0: excellent temperature (k) of gas medium under operation condition

金属管浮子流量计的结构

Structure of metal tube rotameter

1、高温型结构(G型)

1. High temperature structure (type G)

高温结构型(G型)是用于介质温度过高或过低而需要对测量管采取保温隔热措施的介质的流量测量。高温型结构是加大了测量管与指示器之间的距离来增加散热、增加隔热材料厚度,保证指示器工作在允许的环境温度范围内。选型为"G"型。

The high temperature structure type (G type) is used to measure the flow rate of the medium which needs to take heat insulation measures for the measuring pipe because of the medium temperature is too high or too low. High temperature structure is to increase the distance between the measuring tube and the indicator to increase heat dissipation, increase the thickness of thermal insulation material, and ensure that the indicator works in the allowable ambient temperature range. The type selection is "g".

G型金属管浮子流量计可以测量温度达-80℃-+300℃的介质的流量。

G-type metal tube rotameter can measure the flow rate of medium with temperature up to - 80 ℃ - + 300 ℃.

2、带阻尼器装置的结构(Z型)

2. Structure with damper (Z-type)

阻尼器结构型用于流量计入口流量(压力)不稳定时的介质流量测量,特别是对于气体的测量。它的结构如图所示.

The damper structure is used to measure the medium flow rate when the inlet flow rate (pressure) is unstable, especially for gas measurement. Its structure is shown in the figure

3、夹套型结构(T型)

3. Jacket type structure (T type)

夹套型结构用于对需要伴热或冷却(如高粘度和易结晶)的介质的流量测量。在夹套中通过加热或冷却介质,使低沸点、低凝固点流体不汽化和不结晶。

The jacket type structure is used to measure the flow rate of the medium which needs heat tracing or cooling (such as high viscosity and easy crystallization). By heating or cooling the medium in the jacket, the fluid with low boiling point and low freezing point is not vaporized and crystallized.

伴热介质的导入和导出连接,标准型要用HG20594-97 DN15 PN1.6法兰,其它的法兰规格连接可与生产厂标明,夹套的压力等级为1.6MPa.

Hg20594-97 DN 15 pn1.6 flange shall be used for the leading in and leading out connection of heat tracing medium. Other flange specification connection can be indicated with the manufacturer. The pressure grade of jacket is 1.6Mpa

夹套型流量计结构见FA标准型流量计法兰、外形尺寸图。

See the flange and outline dimension drawing of FA standard flowmeter for the structure of jacketed flowmeter.

4、高压型结构(Y型)

4. High pressure structure (Y type)

高压型结构用于被测介质压力大于标准的压力等级的流量测量。高压型结构如下图所示。目前FFM64系列的*高压力可以达到32MPa。另外高压型流量计可提供内置磁过滤器型,安装高度均为350mm。FA、FB和FC型*大压力为10MPa.

High pressure structure is used for flow measurement when the pressure of the measured medium is greater than the standard pressure level. The high pressure structure is shown in the figure below. At present, the * high pressure of ffm64 series can reach 32Mpa. In addition, the high-pressure flowmeter can be provided with built-in magnetic filter, and the installation height is 350mm. The pressure of FA, FB and FC * is 10MPa