Flow meter

推荐资讯

免费咨询热线

+086-0517-86998608Flow meter

智能涡街流量计是根据卡门涡街理论,利用了流体的自然振动原理,以压电晶体或差动电容作为检测部件而支撑的一种速度式流量仪表。本产品采用独特的差动技术,配合隔离、屏蔽、滤波等措施,克服了同类产品抗震性差、噪声大、小信号数据紊乱等问题,并采用了独特的检测探头封装新技术和防护措施,保证了产品的可靠性。Intelligent vortex flowmeter is based on Karman vortex street theory and the natural vibration principle···

全国服务热线:+086-0517-86998608

在线咨询-

产品详情

智能涡街流量计是根据卡门涡街理论,利用了流体的自然振动原理,以压电晶体或差动电容作为检测部件而支撑的一种速度式流量仪表。本产品采用独特的差动技术,配合隔离、屏蔽、滤波等措施,克服了同类产品抗震性差、噪声大、小信号数据紊乱等问题,并采用了独特的检测探头封装新技术和防护措施,保证了产品的可靠性。

Intelligent vortex flowmeter is based on Karman vortex street theory and the natural vibration principle of fluid. It is supported by piezoelectric crystal or differential capacitance as detection component. This product adopts unique differential technology, combined with isolation, shielding, filtering and other measures to overcome the problems of similar products such as poor seismic resistance, large noise, small signal data disorder, etc., and adopts a unique detection probe packaging new technology and protection measures to ensure the reliability of the product.

产品有基本型、差压型、温压补偿一体型三种测量方式,基本型测量单一工况流量信号,差压补偿型直接测量质量流量,温压补偿一体型可同时测量温度、压力、流量信号,经补偿后输出标况体积流量或质量流量。产品有管道式和插入式两种结构形式,可现场显示,也可远距离传输,每种型式都有高温、高压、防腐、防爆等规格,又有整体和分体结构,以适应不同的测量介质和安装环境。

The product has three measurement methods: basic type, differential pressure type and temperature pressure compensation type. The basic type measures the flow signal under single working condition, and the differential pressure compensation type directly measures the mass flow. The temperature and pressure compensation type can simultaneously measure the temperature, pressure and flow signals, and output the volume flow or mass flow under standard conditions after compensation. There are two types of products: pipeline type and plug-in type, which can be displayed on site or transmitted over a long distance. Each type has specifications of high temperature, high pressure, anti-corrosion and explosion-proof, as well as integral and split structure to adapt to different measuring media and installation environment.

该系列具有量程比宽、精度高,安装维护方便和介质适应性广等一系列优点。可广泛应用于石油、化工、冶金、机械、食品、造纸、医药、以及城市管道供热、煤气等行业的各种低粘度液体、其他、蒸汽等单相流体的工艺计量和节能管理。

This series has a series of advantages, such as wide range ratio, high precision, convenient installation and maintenance and wide adaptability of medium. It can be widely used in the process measurement and energy-saving management of low viscosity liquid, other single-phase fluid, steam and other single-phase fluids in petroleum, chemical, metallurgy, machinery, food, papermaking, medicine, urban pipeline heating, gas and other industries.

智能涡街流量计原理

Principle of Intelligent Vortex Flowmeter

涡街流量计是利用卡门涡街原理进行流量测量的。在测量管中垂直插入一个柱状物时,流体通过柱状物两侧就自然交替地产生有规则的漩涡(如下图所示),这种漩涡列被称为卡门涡街。在d/D=0.281时,释放的漩涡非常稳定。

Vortex flowmeter is based on the principle of Karman vortex street flow measurement. When a cylinder is inserted vertically into the measuring tube, the fluid will naturally and alternately generate regular vortices (as shown in the figure below) when the fluid passes through the two sides of the cylinder. This kind of vortex array is called Karman vortex street. When D / D = 0.281, the released vortex is very stable.

(D为管道直径。)卡门涡街的释放频率与流体的流动可用下式表示:

(D is the pipe diameter.) The release frequency of Karman vortex street and fluid flow can be expressed as follows:

F=st?v/d 式中:

F = St? V / D, where:

F————————卡门涡街的释放频率

F -- release frequency of Karman vortex street

St————————系数

-- st -- coefficient

V—————————流速

V -- velocity

d—————————柱状物宽度

D -- width of column

斯特罗哈系数是涡街流量计的重要系数,在一定的雷诺数范围内,斯特罗哈数接近常数。如下图所示,在曲线的St=0.17平直部分,漩涡释放频率与流速成正比,检出频率f就可求得流速v,由v求出体积流量。用于测量流量的漩涡分离频率随流速而变化,不受流体密度和粘度的影响。伴随漩涡分离而产生的局部压力脉动,有压电探头检测出来,并在检测电路中被转换成与漩涡频率相对应的脉冲信号。脉冲信号还可以通过F/V和V/I转化成4-20mA的标准电流信号输出。

Strouhal coefficient is an important factor of vortex flowmeter. In a certain range of Reynolds number, Strouhal number is close to a constant. As shown in the figure below, in the straight part of the curve with ST = 0.17, the vortex release frequency is directly proportional to the flow rate. The detection frequency f can obtain the velocity V, and the volume flow rate can be obtained from V. The vortex separation frequency used to measure the flow rate varies with the flow rate and is not affected by the density and viscosity of the fluid. The local pressure pulsation caused by vortex separation is detected by piezoelectric probe and converted into pulse signal corresponding to vortex frequency in detection circuit. The pulse signal can also be converted into 4-20mA standard current signal output through F / V and V / I.

智能涡街流量计性能参数

Performance parameters of Intelligent Vortex Flowmeter

1 公称口径:DN15、DN20、DN25、DN32、DN40、DN50、DN65、DN80、DN100、DN125、DN150、DN200、DN250、DN300、DN250~DN2000可选用插入式:

1. Nominal diameter: DN 15, DN20, DN25, DN32, Dn40, DN50, DN65, DN80, DN 100, DN 125, DN 150, DN200, DN250, DN300, DN250 ~ DN2000. Plug in type can be selected

2 使用范围:气体(空气、氧气、但其、煤气、天然气、化学气体等)、液体(谁、高温水、油、食品液、化学液等)、蒸汽(饱和蒸汽、过热蒸汽)

Scope of application: gas (air, oxygen, gas, natural gas, chemical gas, etc.), liquid (high temperature water, oil, food liquid, chemical liquid, etc.), steam (saturated steam, superheated steam)

3 可测介质温度:-40℃~280℃,-40℃~350℃

3. Measurable medium temperature: - 40 ℃ ~ 280 ℃, - 40 ℃ ~ 350 ℃

4 公称压力:≦1.6Mpa ≦2.5Mpa ≦4Mpa

4. Nominal pressure: ≤ 1.6Mpa ≤ 2.5MPa ≤ 4MPa

5 精度等级:液体0.5级、气体、蒸汽1.0级,插入式2.5级

5 accuracy class: liquid 0.5, gas and steam 1.0, plug-in type 2.5

6 流速范围:液体0.6-6m/s,气体:5-60m/s蒸汽:5-70m/s

6 flow rate range: liquid 0.6-6 M / s, gas: 5-60 M / s, steam: 5-70 M / s

7 输出信号:

7 output signal:

电压脉冲:低电平≦1V,高电平≧6V,脉冲宽0.4ms,负载电阻>150

Voltage pulse: low level ≤ 1V, high level ≥ 6V, pulse width 0.4ms, load resistance > 150

标准电流:4-20mA,转换精度0.1%,累计流量9位显示(m3、kg、t),转换精度0.1%

Standard current: 4-20mA, conversion accuracy 0.1%, cumulative flow 9-bit display (M3, kg, t), conversion accuracy 0.1%

8 供电电源:

8 power supply:

电压脉冲输出时:+12VDC,4-20mA输出时:+24VDC

Voltage pulse output is + 12VDC, 4-20mA output is + 24VDC

现场液晶显示:3.6V1号1节锂电池供电,使用寿命大于2年

LCD: 3.6v1 1 lithium battery power supply, service life more than 2 years

9 环境温度:电压脉冲输出:-30℃~+65℃,4-20mA输出:-10℃~+55℃,现场液晶显示:-25℃~+55℃

9 ambient temperature: voltage pulse output: - 30 ℃ ~ + 65 ℃, 4-20mA output: - 10 ℃ ~ + 55 ℃, on-site LCD: - 25 ℃ ~ + 55 ℃

10 表体材料:1Cr18Ni9Ti(其他材料协议供货)。

10 table body material: 1Cr18Ni9Ti (supplied by other materials agreement).

11、防爆等级本安型iaIIbT3-T6、防护等级IP65

11. Explosion proof grade intrinsic safety type iaiibt3-t6, protection grade IP65

涡街流量计优势特点

Advantages of vortex flowmeter

1、智能涡街流量计的非常大优点是抗振性能特别好,无零点漂移,可靠性高

1. The great advantage of intelligent vortex flowmeter is its excellent anti vibration performance, no zero drift and high reliability

2、抗振性能特别好通过长时间对涡街流量计进行大量波形分析和频谱分析。新航设计出了非常佳的探头形状、壁厚、高度、探头杆直径及与之相配套的压电晶体,采用先进的数控车床进行加工,确保加工的同轴度和光洁度等技术参数。配合特殊的工艺处理。从而非常大限度的克服涡街流量计存在的固有自震荡频率对信号的影响这个通病。这是新航公司在制造涡街流量计方面的技术独特优势。使得新航公司出厂的涡街流量计有优良的抗振动能力。

2. The anti vibration performance is particularly good. A lot of waveform analysis and frequency spectrum analysis of vortex flowmeter are carried out for a long time. SIA has designed a very good probe shape, wall thickness, height, probe rod diameter and its matching piezoelectric crystal, which is processed by advanced CNC lathe to ensure the technical parameters such as coaxiality and smoothness. With special process treatment. Therefore, it overcomes the common problem of the influence of the inherent self oscillation frequency on the signal of the vortex flowmeter to a great extent. This is the unique technical advantage of SIA in manufacturing vortex flowmeter. The vortex flowmeter manufactured by SIA has excellent anti vibration ability.

3、智能涡街流量计的传感器的通用性很强,从而使得传感器具有良好的互换性。采用先进的数控设备加工传感器的表体和漩涡发声体等,确保加工精度,从而使得零部件(特别是漩涡发声体)的通用性强,从而真正做到不会因零部件的更换而影响传感器的重复性和精度,能产生强大而稳定的涡街信号。

3. The sensor of intelligent vortex flowmeter has strong universality, which makes the sensor have good interchangeability. Advanced numerical control equipment is used to process the sensor body and vortex generator to ensure the machining accuracy, so as to make the parts (especially the vortex generator) have strong versatility, so that the repeatability and accuracy of the sensor will not be affected by the replacement of parts, and the strong and stable vortex street signal can be generated.

Instrument diameter (mm) | liquid | Gas | ||

measuring range (m3/h) | Output frequency range (Hz) | measuring range (m3/h) | Output frequency range (Hz) | |

15 | 0.3~5 | 35~450 | 3~15 | 300~1600 |

20 | 0.6~10 | 29~380 | 6~30 | 230~1200 |

25 | 1.2~16 | 25~320 | 8.8~52 | 170~1100 |

32 | 1.8~20 | 18~200 | 10~120 | 100~1180 |

40 | 2~40 | 10~190 | 27~205 | 130~1040 |

50 | 3~60 | 8~150 | 35~380 | 94~920 |

65 | 4~85 | 6~120 | 60~640 | 90~910 |

80 | 6.5~130 | 4.1~82 | 86~1100 | 55~690 |

100 | 15~220 | 4.7~69 | 133~1700 | 42~536 |

125 | 20~350 | 3.2~57 | 150~2000 | 38~475 |

150 | 30~450 | 2.8~43 | 347~4000 | 33~380 |

200 | 45~800 | 2~31 | 560~8000 | 22~315 |

250 | 65~1250 | 1.5~25 | 890~11000 | 18~221 |

300 | 95~2000 | 1.2~24 | 1360~18000 | 16~213 |

(300) | 100~1500 | 5.5~87 | 1560~15600 | 85~880 |

(400) | 180~3000 | 5.6~87 | 2750~27000 | 85~880 |

(500) | 300~4500 | 5.6~88 | 4300~43000 | 85~880 |

(600) | 450~6500 | 5.7~89 | 6100~61000 | 85~880 |

(800) | 750~10000 | 5.7~88 | 11000~110000 | 85~880 |

(1000) | 1200~17000 | 5.8~88 | 17000~170000 | 85~880 |

>(1000) | 协议 | 协议 | ||

注:表中(300)~(1000)口径为插入式

Note: the diameters of (300) ~ (1000) in the table are plug-in type

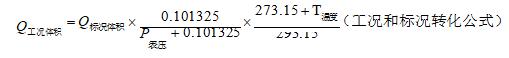

工况流量是指仪表测量出当前通过管道介质的体积,是在工作状态下的介质,例如气体是可以被压缩的,在管道内存在压力时,气体被压缩后的体积就是工况流量。工况流量会随着工作环境改变而改变。

Working condition flow refers to the volume of medium passing through the pipeline measured by the instrument, which is the medium under working condition. For example, gas can be compressed. When there is pressure in the pipeline, the volume of compressed gas is the working flow. The flow rate will change with the change of working environment.

标况流量是指介质在标准大气压力下和 0°(或 20°)标准下的体积,当压缩气体被释放到标况环境中转化的体积。标况流量在任何环境中均不会发生改变。

Standard flow rate refers to the volume of medium under standard atmospheric pressure and 0 ° (or 20 °) standard, and the volume converted when compressed gas is released into standard environment. The standard flow rate will not change in any environment.

涡街流量计测量得出的是工况体积,只有做温压补偿后才可以得出标况体积,一般用于贸易计量时, 气体采用标况为主,蒸汽通常采用质量计量。

The volume measured by vortex flowmeter is the working condition volume, and the standard volume can be obtained only after temperature and pressure compensation. When it is generally used for trade measurement, the standard condition is mainly used for gas, and the mass measurement is usually used for steam.

气体涡街流量计安厂家仪表管道安装要求

Installation requirements for instrument pipe of gas vortex flowmeter manufacturer

产品安装与使用

Product installation and use

6.1仪表安装环境要求

6.1 environmental requirements for instrument installation

1.流量计应安装在室内,如果安装在室外,上面应有遮盖物,以防雨水侵入和烈日暴晒而影响流量计的使用寿命(流量计接线时屏蔽线要做成 U 型,非常后进入表壳时线路为从下往上,避免雨水沿线路进入到表壳内部);

1. The flowmeter should be installed indoors. If it is installed outdoors, it should be covered to prevent rainwater intrusion and sun exposure from affecting the service life of the flowmeter (the shielding wire of the flowmeter should be U-shaped, and the line should be from bottom to top when entering into the case after the connection, so as to avoid rainwater from entering the inside of the meter case along the line);

2.流量计周围不得有强外磁场干扰、强电设备、高频设备,并且避免与这些设备共用电源;

2. There should be no strong external magnetic field interference, strong current equipment and high frequency equipment around the flowmeter, and avoid sharing power with these equipment;

3.不要和变频器、电焊机等污染电源的设备共用电源,必要时加装净化电源;

3. Do not share the power supply with the inverter, welding machine and other equipment that pollute the power supply. If necessary, install the purified power supply;

4.避开高温、寒冷、腐蚀性或极度潮湿的环境,如必须安装必须做好流量计的保护工作;

4. Avoid high temperature, cold, corrosive or extremely humid environment. If it must be installed, the flowmeter must be well protected;

5.流量计应避免安装在振动较强的管道上。若必须安装,须在其上下游 2D 处加设管道紧固装置,并加防振垫,加强抗振效果;

5. The flowmeter should not be installed on the pipeline with strong vibration. If it must be installed, pipeline fastening device and anti vibration pad shall be installed at 2D upstream and downstream to enhance anti vibration effect;

6.仪表安装点周围应该留有较充裕的空间,以便安装接线和定期维护。

6. Sufficient space should be reserved around the instrument installation point for installation, wiring and regular maintenance.

6.2仪表管道安装要求

6.2 installation requirements of instrument pipeline

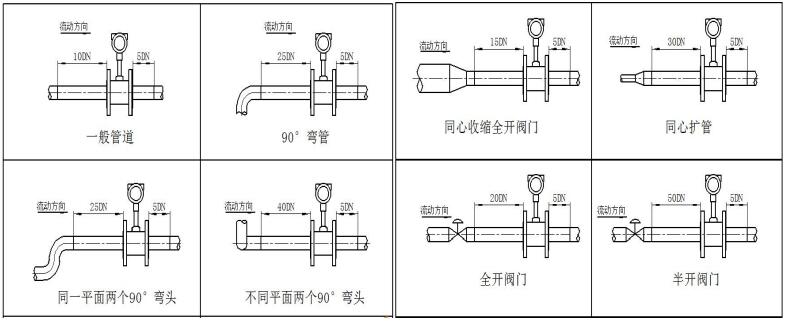

涡街流量仪表对安装点的上下游直管段有一定要求,否则会影响介质在管道中的流场,影响仪表的测量精度。仪表的上下游直管段长度要求见图,DN 为仪表公称通径,单位:mm

Vortex flowmeter has certain requirements for the upstream and downstream straight pipe section of the installation point, otherwise it will affect the flow field of medium in the pipeline and the measurement accuracy of the instrument. The length requirements of upstream and downstream straight pipe sections of the instrument are shown in the figure. DN is the nominal diameter of the instrument, unit: mm

注: 1、调节阀尽可能不安装在涡街流量仪表的上游,而应安装在涡街流量仪表的下游 10D 以外。

Note: 1. The regulating valve shall not be installed upstream of vortex flowmeter as far as possible, but shall be installed outside 10d downstream of vortex flowmeter.

2、上、下游配管内径应相同。如有差异,则配管内径 Dp 与涡街仪表表体内径 Db,应满足以下关系0.98Db≤Dp≤1.05Db

2. The inner diameter of upstream and downstream piping should be the same. If there is any difference, the relationship between the inner diameter of piping DP and the inner diameter of vortex meter body DB shall be 0.98db ≤ DP ≤ 1.05db

3、上、下游配管应与流量仪表表体内径同心,它们之间的不同轴度应小于 0.05Db

3. The upstream and downstream piping should be concentric with the inner diameter of the flow meter body, and the different axial degrees between them should be less than 0.05db

4、仪表与法兰之间的密封垫,在安装时不能凸入管内,其内径应比表体内径大 1-2mm

4. The gasket between the instrument and the flange should not protrude into the pipe during installation, and its inner diameter should be 1-2mm larger than the inner diameter of the body

5、测压孔和测温孔的安装设计。被测管道需要安装温度和压力变送器时,测压孔应设置在下游 3-5D处,测温孔应设置在下游 6-8D 处。D 为仪表公称口径,单位:mm

5. Installation design of pressure measuring hole and temperature measuring hole. When the measured pipeline needs to install temperature and pressure transmitter, the pressure measuring hole should be set at the downstream 3-5d, and the temperature measuring hole should be set at the downstream 6-8d. D is the nominal diameter of the instrument in mm

6、仪表在管道上可以水平、垂直或倾斜安装。

6. The instrument can be installed horizontally, vertically or obliquely on the pipeline.

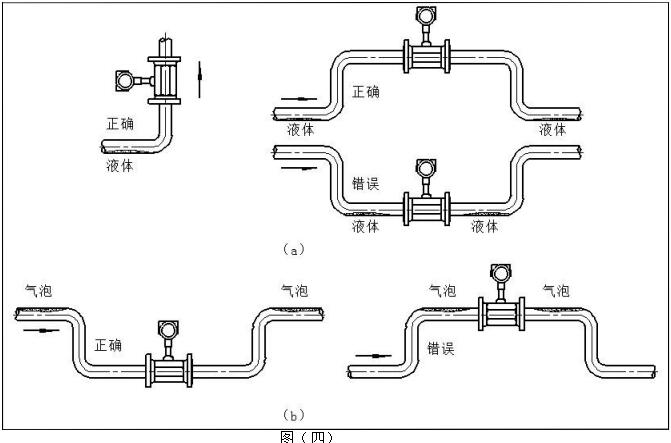

7、测量气体时,在垂直管道安装仪表,气体流向不限。但若管道内含少量液体,为了防止液体进入仪 表测量管,气流应自下而上流动,如图(四)a 所示

7. When measuring the gas, install the instrument in the vertical pipe, and the gas flow direction is unlimited. However, if the pipeline contains a small amount of liquid, the air flow should flow from bottom to top in order to prevent liquid from entering the instrument measuring tube, as shown in Fig. (4) a

8、 测量液体时,为了保证管内充满液体,所以在垂直或倾斜管道安装仪表时,应该保证液体流动方向从下而上。若管道内含少量气体,为了防止气体进入仪表测量管,仪表应安装在管线的较低处如图(四)b 所示

8. When measuring liquid, in order to ensure that the pipe is full of liquid, when installing the instrument in vertical or inclined pipeline, the liquid flow direction should be ensured from bottom to top. If the pipeline contains a small amount of gas, in order to prevent the gas from entering the instrument measuring pipe, the instrument should be installed at the lower part of the pipeline, as shown in Fig. (4) B

9、测量高温、低温介质时,应注意保温措施。转换器内部(表头壳体内)高温一般不应超过 70℃;低温易使转换器内部出现凝露,降低抑

9. When measuring high temperature and low temperature medium, attention should be paid to heat preservation measures. The internal temperature of the converter should not be lower than 70 ℃

制电路板的绝缘阻抗,影响仪表正常工作。

The insulation impedance of the circuit board affects the normal operation of the instrument.

6.3插入式涡街流量仪表安装步骤

6.3 installation steps of plug-in vortex flowmeter

1.在管道上用气焊开一个略小于φ100mm 的圆孔,并把圆孔周围毛刺清除干净,以保证测头旋转流利;

1. Use gas welding to open a round hole slightly smaller than φ 100 mm on the pipe, and remove the burr around the round hole to ensure the smooth rotation of the probe;

2.在管道圆孔处焊上厂家提供的法兰,要求法兰轴线与管道轴线垂直;

2. The flange provided by the manufacturer shall be welded on the pipe round hole, and the flange axis shall be vertical to the pipeline axis;

3.将球阀及传感器安装在焊接好的法兰上;

3. Install the ball valve and sensor on the welded flange;

4.调节丝杠,使插入深度符合要求(保证测头中心轴线和管道中心轴线重合),流体流向必须与方向标上的指示箭头保持一致;

4. Adjust the lead screw to make the insertion depth meet the requirements (ensure that the central axis of the probe coincides with the central axis of the pipeline), and the fluid flow direction must be consistent with the indication arrow on the direction indicator;

5.均匀拧紧压盖上的螺丝。(注:压盖的松紧程度决定仪表的密封程度和丝杠能否旋动);

5. Tighten the screws on the gland evenly. (Note: the tightness of the gland determines the sealing degree of the instrument and whether the screw can rotate or not);

6.检查各环节是否完成好,慢慢打开阀门观察是否有泄漏(需特别注意人身安全)若有泄露请重复步骤 5、6。

6. Check whether all links are completed, slowly open the valve to observe whether there is leakage (pay special attention to personal safety). If there is leakage, please repeat steps 5 and 6.

智能涡街流量计选型

Selection of Intelligent Vortex Flowmeter

Type spectrum of vortex flowmeter | explain | |||||||||||||||

Piezoelectric vortex flowmeter Capacitive vortex current counter | Instrument type | |||||||||||||||

2 3 4 5 6 7 8 | Flange clamping type Flange connection Pipe butt joint type Threaded connection Clamp connection type Fixed plug in type Ball Punch | Installation mode | ||||||||||||||

2 3 4 | liquid Gas Yanqi | Measuring medium | ||||||||||||||

—X | The nominal diameter of flowmeter is represented by 2-4 Arabic numerals, for example, DN200 is represented by 200 | Nominal diameter | ||||||||||||||

—2 —3 —4 —5 —6 —7 —8 —9 | No display of pulse frequency signal Pulse frequency signal band display Battery powered field display Two wire system 4-20mA signal without display Two wire 4-20mA signal band display Two wire 4-20mA signal with HART Communication Three wire 4-20mA signal band display Three wire 4-20mA signal with r-s485 communication | output signal | ||||||||||||||

2 3 4 5 6 | -50℃ - 50℃(仅电容式) -20℃ - 50℃ 50℃ - 250℃ 50℃ - 320℃ 50℃ - 500℃(仅电容式) | Temperature specification | ||||||||||||||

2 3 4 5 6 | 1.6MPa 2.5MPa 4.0MPa 6.4MPa 更高压力规格(非常高可达32MPa) | Pressure specification | ||||||||||||||

M P T PT | Differential pressure compensation type Pressure compensated type Temperature compensation type Temperature and pressure compensation type | Compensation type | ||||||||||||||

F Q S N G B Y | Split style Diving type Reduced diameter type Corrosion resistant Flameproof type Muan explosion proof plastic Integrated compensation type | Other options | ||||||||||||||

| 3 | 4 | -80 | -6 | 6 | 3 | M | Y | Integrated capacitive differential pressure vortex mass flowmeter, flange The medium is less than 500 ℃. DN80,PN25. Current signal output with display. | |||||||