Flow meter

推荐资讯

免费咨询热线

+086-0517-86998608Flow meter

一、工作原理1、 How it works电磁流量计是根据法拉第电磁感应定律进行流量测量的流量计。电磁流量计的优点是压损小,可测流量范围大。最大流量与最小流量的比值一般为20:1以上,使用的工业管径范围宽,可测量DN10~DN2000范围内的管径,输出信号和被测流量成线性,精确度高,可测量电导率≥5μs/cm的酸、碱、盐溶液、水、污水、腐蚀性液体以及泥浆、矿浆、纸浆等的流体流量。广泛应用于化工、冶金、轻纺、造纸、环保、食品、生活污水、工业污水、冷却水、自来水厂等工业部门以及市政管理、水利建设、河···

全国服务热线:+086-0517-86998608

在线咨询-

产品详情

一、工作原理

1、 How it works

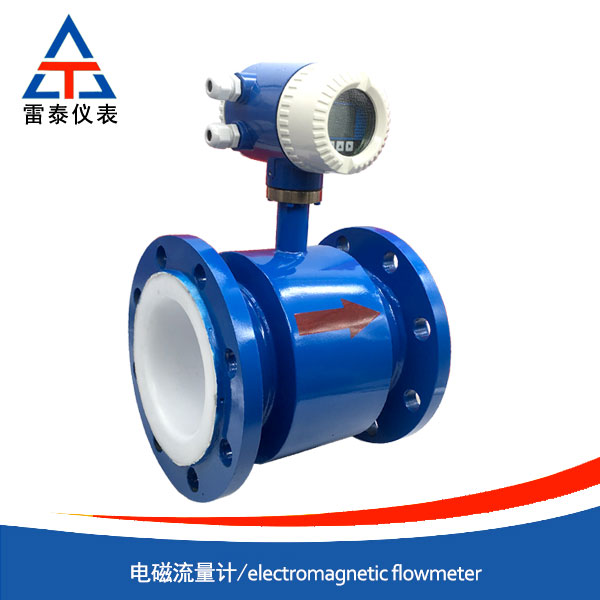

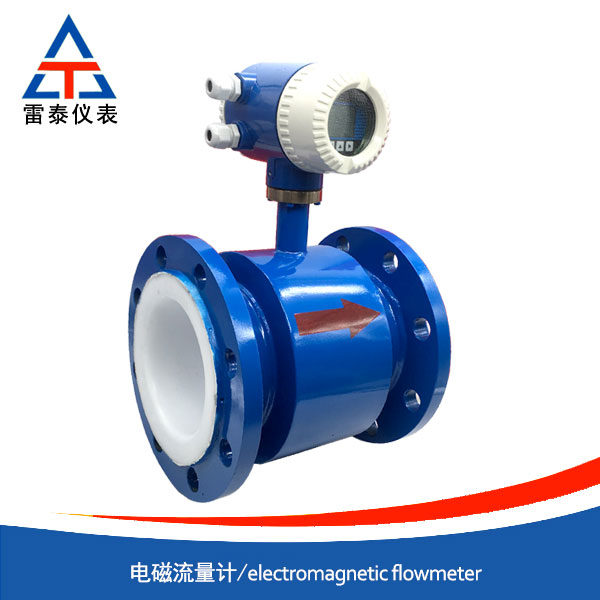

电磁流量计是根据法拉第电磁感应定律进行流量测量的流量计。电磁流量计的优点是压损小,可测流量范围大。最大流量与最小流量的比值一般为20:1以上,使用的工业管径范围宽,可测量DN10~DN2000范围内的管径,输出信号和被测流量成线性,精确度高,可测量电导率≥5μs/cm的酸、碱、盐溶液、水、污水、腐蚀性液体以及泥浆、矿浆、纸浆等的流体流量。广泛应用于化工、冶金、轻纺、造纸、环保、食品、生活污水、工业污水、冷却水、自来水厂等工业部门以及市政管理、水利建设、河流疏浚、楼宇供水计量等领域的流量计计量。

Electromagnetic flowmeter is based on Faraday's law of electromagnetic induction for flow measurement. The advantages of electromagnetic flowmeter are small pressure loss and wide flow range. The ratio of the maximum flow to the minimum flow is generally more than 20:1. The industrial pipe diameter range used is wide, and the pipe diameter within the range of DN 10 ~ DN2000 can be measured. The output signal is linear with the measured flow rate, and the flow rate of acid, alkali, salt solution, water, sewage, corrosive liquid, slurry, pulp, etc. with conductivity ≥ 5 μ s / cm can be measured. It is widely used in chemical industry, metallurgy, textile, papermaking, environmental protection, food, domestic sewage, industrial sewage, cooling water, waterworks and other industrial departments, as well as municipal management, water conservancy construction, river dredging, building water supply measurement and other fields.

二、产品特点

2、 Product features

1、转换显示器采用16位高性能微处理器,2×16LCD显示,参数设定方便,编程可靠

1. The conversion display adopts 16 bit high-performance microprocessor, 2 × 16 LCD display, convenient parameter setting and reliable programming

2、双向测量系统,内装三个积算器可分别显示:正向流量、反向流量及正、反向流量之差的总量

2. Two way measurement system with three integrators can display the total amount of forward flow, reverse flow and the difference between positive and negative flow

3、转换显示器有多种输出:电流、脉冲、数字通讯、HART、485通讯协议

3. Conversion display has a variety of output: current, pulse, digital communication, Hart, 485 communication protocol

4、适用大管径管道,DN300—1400mm

4. Suitable for large diameter pipe, dn300-1400mm

5、传感器本体与电极有多种材料可选

5. There are many kinds of materials for sensor body and electrode

6、体积小、重量轻、运输、安装方便,可实现不断流维护、拆装

6. Small size, light weight, convenient transportation and installation, can realize continuous flow maintenance, disassembly and assembly

Lining material | main performance | Maximum medium temperature | Scope of application | |

All in one | Separable type | |||

teflon(F4) | It is a kind of plastic with stable chemical properties. It is resistant to boiling hydrochloric acid, sulfuric acid, nitric acid and aqua regia, as well as strong alkali and various organic solvents. It is not resistant to the corrosion of chlorine trifluoride, high temperature chlorine trifluoride, high flow rate liquid fluorine, liquid oxygen and self oxygen. | 70℃ | 100℃ 250℃ | 1、浓酸、碱等强腐蚀性介质。 |

Perfluoroethylene propylene(F46) | The wear resistance and negative pressure resistance of F4 are higher than that of F4. | 同上 | ||

Polyfluoroethylene(Fs) | The upper limit of applicable temperature is lower than that of polytetrafluoroethylene, but the cost is also lower. | 80℃ | ||

Polychloroprene rubber | 1. It has excellent elasticity, high breaking force and good wear resistance. 2. It is resistant to corrosion of low concentration acid, alkali and salt medium, but not to oxidation medium. | 80℃ 120℃ | 水、污水、弱磨损性的泥浆矿浆。 | |

Polyurethane rubber | 1、The wear resistance is very strong. | 80℃ | 中性强磨损的矿浆、煤浆、泥浆 | |

2、Poor corrosion resistance. | ||||

Electrode material | Corrosion resistance and wear resistance |

stainless steel 0Crl8Nil2M02Ti | It is suitable for industrial water, domestic water, sewage and other weakly corrosive media. It is suitable for petroleum, chemical, steel and other industrial sectors and municipal, environmental protection and other fields. |

Hastelloy B | It has good corrosion resistance to all concentrations of hydrochloric acid below boiling point, as well as non chlorinated acid, alkali and non oxidizing salt solution such as sulfuric acid, phosphoric acid, hydrofluoric acid and organic acid. |

Hastelloy C | It can resist the corrosion of non oxidizing acid, such as nitric acid, mixed acid, or mixed medium of chromic acid and sulfuric acid, as well as the corrosion of oxidizing salts such as FC +, Cu + or containing other oxidants, such as hypochlorite solution higher than normal temperature and seawater corrosion |

tantalum | It can resist the corrosion of seawater, various chlorides and hypochlorites, oxidizing acids (including fuming sulfuric acid), organic acids and alkalis. It is not resistant to the corrosion of pure reducing acid (such as sulfuric acid and hydrochloric acid), but if the acid contains oxidants (such as nitric acid, FC +, Cu +), the corrosion is greatly reduced. |

tantalum | It has excellent corrosion resistance and is similar to glass. In addition to hydrofluoric acid, fuming sulfuric acid and alkali, it can almost resist the corrosion of a chemical medium (including hydrochloric acid with boiling point, nitric acid and sulfuric acid below 150 ℃). In alkali; corrosion resistant. |

Platinum / titanium alloy | It is resistant to almost all chemical media, but not suitable for aqua regia and ammonium salts. |

Stainless steel coated with tungsten carbide | It is used for non corrosive and strong wear medium. |

Note: due to the variety of media, and its corrosivity is affected by complex factors such as temperature, concentration, flow rate, etc., this table is only for reference. Users should make their own choice according to the actual situation. If necessary, the corrosion resistance test of the materials to be selected, such as coupon test, should be carried out. | |

五、Flow diameter comparison table

caliber mm | Flow range m³/h | caliber mm | Flow range m³/h |

DN10 | 0.16~2.5 | DN400 | 250~4000 |

DN15 | 0.4~6 | DN500 | 400~6000 |

DN20 | 0.6~12 | DN600 | 600~10000 |

DN25 | 1.0~16 | DN700 | 800~12000 |

DN32 | 1.6~25 | DN800 | 1000~16000 |

DN40 | 2.5~40 | DN900 | 1200~20000 |

DN50 | 4.0~60 | DN1000 | 1600~25000 |

DN65 | 6.0~120 | DN1200 | 2500~30000 |

DN80 | 10~160 | DN1400 | 3000~50000 |

DN100 | 16~250 | DN1600 | 3000~60000 |

DN125 | 25~400 | DN1800 | 5000~60000 |

DN150 | 40~600 | DN2000 | 6000~100000 |

DN200 | 60~1000 | DN2200 | 1367.78~136778.4 |

DN250 | 100~1600 | DN2400 | 1627.78~162777.6 |

DN300 | 160~2500 | DN2600 | 1910.38~191037.6 |

DN350 | 200~3000 | DN2800 | 2306.56 ~ 236062.8 |

caliber | ||||||||

10~2600 | ||||||||

Code | Installation form | |||||||

Y | Integrated | |||||||

F | Split style | |||||||

Code | Converter model | |||||||

ZA | circular | |||||||

ZB | Square (split type only) | |||||||

Code | Power supply form | |||||||

AC | (communication)220V AC 50Hz(90~245V AC 50Hz) | |||||||

DC | (communication)24V DC (20~36V DC) | |||||||

LD | Lithium battery power supply (without signal output) | |||||||

Code | ||||||||

I | ||||||||

f | ||||||||

Rs | ||||||||

H | ||||||||

C | ||||||||

Medium temperature | ||||||||

≤65℃ | ||||||||

≤120℃ | ||||||||

≤180℃(Split type only) | ||||||||

Code | Lining material | |||||||

NE | Chloroprene rubber(≤65℃) | |||||||

PVC | polyvinyl chloride(≤70℃) | |||||||

PU | Polyurethane wear resistance (≤80℃) | |||||||

PTFE | teflon(≤180℃) | |||||||

Code | Electrode material | |||||||

316L | stainless steel | |||||||

HC | Hastelloy C | |||||||

Ti | titanium | |||||||

Ta | tantalum | |||||||

Pt | 铂 | |||||||

Warm tips: electromagnetic flowmeter selection is necessary, medium, caliber (flow range), electrode material, lining material, installation method | ||||||||

七、安装注意事项

7、 Installation precautions

1、应安装在水平管道较低处和垂直向上处,避免安装在管道的最高点和垂直向下处图1所示;

1. It should be installed at the lower part of the horizontal pipe and vertically upward, avoiding the installation at the highest point and vertical downward position of the pipeline, as shown in Fig. 1;

2、应安装在管道上上升处;

2. It should be installed at the rising position of the pipeline;

3、在开口排放管道安装,应安装在管道的较低处;

3. For the installation of open discharge pipeline, it should be installed at the lower part of the pipeline;

4、若管道落差超过5m时,在传感器的下游安装排气阀;

4. If the pipeline drop exceeds 5m, an exhaust valve should be installed downstream of the sensor;

5、传感器绝对不能安装在泵的进出口处,应安装在泵的出口处。

5. The sensor must not be installed in the pump inlet and outlet, should be installed in the pump outlet.